TECH ON DISPLAY

At the STIHL Tirol facility

by TurfPro Editor, Laurence Gale MSC, MBPR

Last week I had the pleasure of visiting STIHL's manufacturing facility in Austria and was able to see and test out the new generation of technology which the company is introducing to the professional market.

Last week I was privileged to have been invited to attend, along with my work colleague Steve Gibbs, editor of Service Dealer, a STIHL press trip to one of their manufacturing facilities in Tirol, Austria.

This factory site was formerly the production line for the Viking brand of garden shredders in 1982, before progressing on to making Viking lawn mowers in 1984.

In 1992 STIHL bought out Viking and began the renewal of the range of garden tools they could offer. The company were still producing a range of mowers and selling them under the brand name of Viking. However, in 2017 the process of amalgamation began and by 2019 all products are now being sold with STIHL orange branding.

Viking museum at Tirol

This long-time partnership and acquisition has allowed the STIHL brand to further its strength in both the professional and domestic markets selling a whole new range of garden machinery from small hand tools through to pedestrian and ride on mowers - with an emphasis on cordless and battery powered products.

A substantial investment has been made to develop the site over the years, with the most recent construction phase IV being completed in 2019 with a usable floor space of 20,000 m² (the largest extension of STIHL Tirol to date) virtually doubling the size of the factory site.

A family-owned business based in Germany, STIHL employs more than 17,000 staff worldwide and sells products in more than 160 countries globally. The company’s range spans chainsaws, hedge and grass trimmers, multi-tools, pressure washers, construction tools, lawn mowers, lawn tractors, robotic mowers and other garden equipment.

STIHL GB is a wholly-owned subsidiary of the global STIHL Group. In Great Britain, the company's products are available from more than 700 specialist Approved Dealers who offer expert customer service.

There were over thirty members of the press attending this event. Myself, Steve and a number of other turf professional trade magazines were joined by a large contingent of mainstream gardening press. Journalists who write the gardening columns for national newspapers, magazines and blogs.

It was nice to find out some of their thoughts on our industry and where they saw our industry going in the next few years, particularly on the robotic mower front. They also had the same concerns as me, in how do we encourage the next generation of gardeners and groundsmen to come and work in our industry.

We were met by a delegation of STIHL employees, led by Bernadette Karner Koessl, PR and marketing manager, who welcomed us all to the factory. The day’s visit saw us witness the complete manufacturing process and assembly line of a wide range of STIHL cordless battery products.

At Tirol we were shown, and were able to test, some new handheld machinery, some of which haven't been officially announced yet, including new domestic and professional mowers. Also, we heard of some interesting control developments for the iMows.

The new smart integration for the robots means the autonomous units can now be issued commands via smart watches integrated with the iMow app; via Amazon Alexa; and via innogy SmartHome, which is an advanced home control system being integrated into some new-build housing. STIHL also said how they were in negotiations with other smart control providers like Google Assistant to establish contracts with those guys as well.

There is no doubt that the popularity of these new smart robotic mowers will increase in the UK market in the coming years. Local machinery dealers are already seeing a large increase in sales year upon year.

With the rapid advancement in GPS tracking technologies I am also sure it will not be long before we can map out our mowing areas via use of a smart phone and send the relevant information to these intelligent mowers thus improving the performance and productivity of these machines.

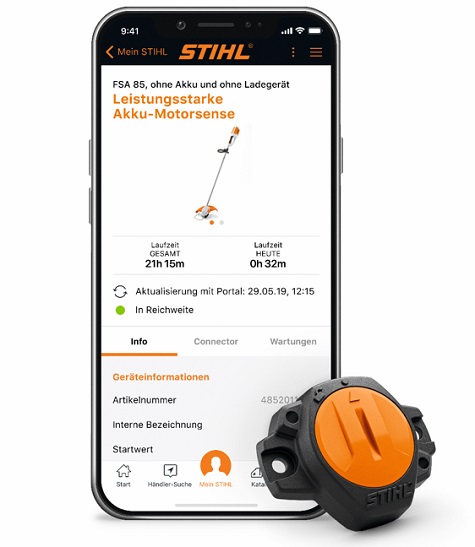

I was also impressed with their STIHL Connected system that gives professional users a detailed overview of key power tool data via a portal in order to enhance maintenance programmes and fleet management efficiencies.

STIHL Connected comprises three central system components; STIHL Smart Connector, STIHL app, and STIHL connect pro portal. When used in conjunction, the system enables professional users to analyse key machinery performance data that can be used to ‘improve daily work processes’, and also help achieve optimum task scheduling.

The pro portal enables the digital management of an entire machinery fleet, meaning users can add or remove power tools, schedule work and view pending maintenance appointments. Users can also see the last position of an active power tool, giving them complete visibility of the whereabouts of any tool, as long as location services on the connected phone are enabled

Developments like this all could have the potential to appeal to tech savvy youngsters, who might be interested in working in a sector where it will be commonplace for them to deal with the latest gadgets.

STIHL told the press they are very much still a premium brand, albeit one with an eye on both ends of the market, with battery products for both entry-level domestic consumers and high-end professional users.

With companies such as these in the industry, investing heavily in new product development and, crucially, in marketing these the products to the public to increase awareness of what's going on in our sector, it would be great to think we can enter the new decade with a positive outlook.

I would like to take this opportunity to thank everybody at STIHL for their kind generosity and hospitality and wish them a happy Christmas and prosperous New Year.

There’s no doubt, we will be seeing a lot more intriguing new cordless products coming to market in the next few years for both the professional and domestic markets.

|

|

|  |

RECORD SET BY JOHN DEERE TRAINING

66 young parts & service technicians

This week's WEB ONLY story is that this year’s John Deere Ag Tech, Parts Tech and Turf Tech advanced apprenticeship programmes have seen the highest total intake since the first Ag Tech induction in 1992.

STOWMARKET GC COMMITS TO FIRST FLEET DEAL

With Toro & Reesink Turfcare

Club say they are investing in the future and are focusing on making sure the course can stay open for play all year round.

As part of a significant investment project, Stowmarket Golf Club has committed to its first fleet deal with Toro and distributor Reesink Turfcare.

Stowmarket Golf Club, set in Finborough Park in Suffolk, has long been a Toro customer, but this is the first time it has bought multiple machines together.

Stowmarket Golf Club course manager, Matt Gill, on the club’s new Toro Reelmaster 6700

Matt Gill, who has been at the club since 1989 and course manager for the last 13 years, said, “We’re investing in the future of the club and Toro is very much a part of that. We’re focusing on making sure the course can stay open for play all year round. We have been making improvements, enlarging our tees, overseeding fairways and improving the drainage and pathways. Not only are we keen to ensure that our members can play all year round, but that they can play uninterrupted for as long as possible each day, which is an area where Toro is key.

“In this deal we’re replacing our existing Reelmaster 6700, a machine that has performed consistently and constantly for 11 years, ensuring we’re always ready for play by 9.30am. I wanted the continuity of Toro and although the old machine is still going strong, we demonstrated a number of five unit machines but opted for the wider machine again, ensuring minimal disruption and increasing productivity.”

As well as a new RM6700, Matt has chosen a Workman HDX-D utility vehicle with a Multi Pro 200 sprayer and Pro Pass 200 top dresser, about which Matt says: “We’ve been thinking about how to tackle the pitchmarks on a regular basis and the solution is to use the top dresser. Since the multi-tasking Workman and top dresser arrived we’ve made great savings in the time spent applying sand and incurring much less disruption as we do it.”

Matt explains the value the new sprayer and top dresser will have maintaining the club’s recent investment in the fairways: “We've heavily invested in the fairways in the last two years due to the drought and it’s important we safeguard that investment. The ability to easily transform the Workman into either a utility vehicle, a precision sprayer or an effective top dresser in only 20 minutes is going to be particularly useful for that and ensuring optimum grass growth.”

Matt continued, "Working with Reesink, and in particular Reesink’s area manager Julian Copping over this time, has been like working with friends, that’s why we’re now making this investment with Toro in our first fleet deal.”

|  |

DENNIS ROTARY PRAISED AT WELSH NATIONAL FACILITY

Colliers Park using PRO 34R

The FAW’s brand new development centre has two natural turf pitches and a synthetic pitch to maintain to the standard expected by a national footballing body.

Dylan Thompson, grounds maintenance manager at Colliers Park, has said that the Dennis PRO 34R "far exceeds" every other rotary mower he has used in the past.

The former Sheffield Wednesday FC assistant head groundsman has been in the top role at Colliers Park for six months now and is already making his mark. With all eyes on the FAW’s brand new development centre, Dylan and his two members of staff are helping to maintain the two natural turf pitches and the synthetic pitch to the standard expected by a national footballing body.

The FAW left no stone unturned in the launch of Colliers Park and Dylan found himself in the fortunate position of receiving an arsenal of brand-new turf maintenance products - two of which were Dennis PRO 34R’s.

“To be honest, the PRO 34R was the machine I wanted most and this was based on my previous experience of using Dennis Mowers,” he said. “I had heard about it on social media and I spoke to other people in the industry - I heard so many good things about it and to not hear anything negative whatsoever was obviously a massive positive.”

The machine is a rotary mower which the company says has been designed to help groundsmen achieve an aesthetically pleasing appearance and desired playing surface. It is suitable for sports pitches and lawns producing the ‘Dennis Stripes’ while a powerful vacuum flow collects debris.

Dylan continued, "The clean-up is absolutely fantastic no matter if it is wet or dry and it sucks up so much into the grass collection box. It is also quick so we are saving time. We have tight turnarounds so the size of these mowers is ideal because you can get so much done in little time.

“We try to use them after every usage but we actually use them during the week as well. It has surprised me as to how good the front brush is. If there is any dew in the morning, then it will take that straight off and it can also pick up any leaves. The finish they leave is really good and you can hardly tell the difference in cut between this and a cylinder mower."

|  |

DOOSON BOBCAT TO ACQUIRE GROUNDSCARE BRANDS

BOB-CAT Mowers plus Steiner and Ryan

It has reported in the U.S that Doosan Bobcat Inc. is to acquire the assets of the BOB-CAT Mowers, and the Steiner and Ryan brands of groundscare equipment from Schiller Grounds Care Inc.

It has reported in the U.S that Doosan Bobcat Inc. is to acquire the assets of the BOB-CAT Mowers, and the Steiner and Ryan brands of groundscare equipment from Schiller Grounds Care Inc.

The transaction is expected to close by December 31st 2019, subject to customary closing conditions and approvals.

“As a pillar of our growth strategy, this acquisition will complement our existing business and expand our footprint to additional, growing industries,” Scott Park, president and chief executive officer of Doosan Bobcat Inc is quoted in U.S trade magazine, Rural Lifestyle Dealer. “These successful brands bring market leadership and closely align with our vision, which will further diversify our business as we expand the reach of Doosan Bobcat to more customers and markets.”

Under the agreement, Doosan Bobcat will acquire the Johnson Creek, Wisconsin, manufacturing facility, and the BOB-CAT Mowers, Steiner and Ryan brands of ground care equipment. The Schiller Grounds Care, Inc. employees working at the Johnson Creek location, as well as the distributor and dealer direct field sales and technical support teams, will join the Doosan Bobcat team once the acquisition is finalised.

“We see tremendous opportunity in these brands and the grounds care industry,” said Mike Ballweber, president of Doosan Bobcat North America. “We look forward to welcoming these employees to our North America team and are excited about what we will be able to accomplish together.”

The purchase price of the assets of the BOB-CAT Mowers, Steiner and Ryan brands of ground care equipment from Schiller Grounds Care, Inc. was not disclosed. BDO Capital Advisers LLC served as the exclusive financial advisor to Schiller Grounds Care Inc.

|  |

FOURTH VENTRAC BOUGHT BY CLUB COMPANY

Delivered to Woodbury Park Hotel

The company which owns and operates 14 Country Clubs across the UK, has praised the machines' use, especially in wet conditions.

The Club Company, which owns and operates 14 Country Clubs across the UK, has taken delivery of a further Ventrac 4500 compact tractor with Contour mowing deck and blower attachments. This latest combination has been delivered to Woodbury Park Hotel, Golf and Leisure near Exeter and brings the total of Ventrac machines within the group to four.

A Ventrac with Turbine Blower at The Tytherington

Chris Brook is the group courses manager, with responsibility for all greenkeeping activities across the company. He is also the course manager at the company’s flagship property, Castle Royle Golf and Country Club near Reading.

“We already have three Ventracs across the group and they have performed exceptionally well,” he said. “They are brilliant in wet conditions as they only generate 6 psi and can get out onto the course when other equipment would seriously damage the surfaces. This Ventrac at Woodbury Park is our fourth within the group, the other three being at Nizels Golf and Country Club in Kent, The Club at Meyrick Park in Bournemouth and The Tytherington near Macclesfield.

“I was quite sceptical when the machine arrived for a demonstration at Castle Royle back in 2017, but was pleasantly surprised, and delighted, at the machine’s capabilities. Considering it is under 25hp it is remarkably powerful and can go anywhere.”

The third machine in the group was delivered to The Tytherington in 2018, where the golf course was constructed using clay spoil from the building of the housing estate back in the 1960s. The underlying clay profile can be quite wet during the winter months and difficult to maintain.

Course Manager Gareth Tucker is in his second spell with the group. He was Deputy Course Manager in 2015 before taking up the post of Course Manager at Glossop; two years later he returned in his current role.

“This is an exceptional machine combination,” he said. “Unlike some parts of the country, we had a very wet summer and it has continued into the autumn. This has created some challenges for the greenkeeping team, but the Ventrac has got us out of jail on many occasions. With its minimal ground pressure it can go out in all weather."

|  |

SODEXO POWERS UP BATTERY USE

Partnership with Husqvarna

The facilities management company now has a policy to use battery-powered products where possible.

Facilities management company, Sodexo, say they are committed to sourcing responsibly and providing services that reduce carbon emissions.

As such, over the past five years the company has steadily increased the use of battery-powered products supplied by Husqvarna and now has a policy to use battery-powered products where possible.

David Ramsay, plant manager at Sodexo Horticultural Services has overseen the adoption of professional battery products and, after trials with several manufacturers, decided upon Husqvarna. He said, “Husqvarna battery products are playing a major role in helping us reduce the impact our services have on the environment by reducing the amount of petrol and diesel we use. The change towards battery-powered products has taken some time, but we are happy that we have been able to make the move.”

He continued: “The battery-powered products we are using are performing beyond what we were expecting. Each product is comfortable, lightweight and easy to use for our landscapers, which has increased staff productivity as they are able to use the products for longer periods.”

David added: “The use of battery products has changed the way our staff work. Many of our jobs are in locations such as office blocks, cemeteries, schools and housing estates with workers using blowers, hedge trimmers and brushcutters to complete tasks.

“The low noise of battery in comparison to petrol means we no longer cause a disturbance to people in these areas, allowing us to work more quietly and efficiently without stoppages."

David concluded, “At Sodexo, safety is paramount. These battery-powered machines produce less vibration, meaning comfortable operation day-to-day for our teams. We’re very excited to be working with Husqvarna and by supplying its battery-powered products we’ve already seen positive results”.

|  |

FIRST DEALER EMPLOYEES JOIN KUBOTA'S NEW WORK PROGRAMME

Initiative with Coleg Cambria Llysfasi

The Kubota Apprenticeship Scheme, a three-year block release initiative blending on-the-job experience with education, has unveiled its first intake.

Coleg Cambria Llysfasi and Kubota have joined forces to launch the Kubota Apprenticeship Scheme, a three-year block release initiative blending on-the-job experience with education at the Denbighshire site.

The Scheme has now unveiled its first cohort, six dealership employees who travelled from as far as Yorkshire and Northampton to attend the course.

The group will reside in student accommodation at Llysfasi, near Ruthin, during each four-week block, and on completion will have achieved a City and Guilds Level 3 Advanced Technical Extended Diploma in Land-Based Engineering.

Tutor Simon Parker, a lecturer in Agricultural Engineering, says interest in the Scheme is growing all the time.

“There has been a lot of buy-in from dealerships and partners across the country, so we’re really pleased,” he said.

“The trainees are already enjoying being part of the community here at Llysfasi, and the nature of the qualification means they will be able to stay in full-time employment while taking time out to study with us."

Among the first to sign up was Aimee Hunt from Hardwick Agricultural Engineers Ltd, near Scarborough.

The 16 year-old had planned to join the Army but swapped “tanks for tractors” and looks forward to a career in the sector.

“There is a need out there for more people in this industry, particularly women,” said Aimee.

“I’m proud to be the first girl to join the apprenticeship scheme and to be here at the beginning of what is a great partnership. I saw the opportunity and just went for it, and I encourage other people who want to work in agricultural engineering to do the same.”

Kubota has presented the college with three tractors and will replace them with new vehicles every six months so the trainees are always using the latest technology and equipment.

Michael Bywater, Group Training Manager of Kubota (UK) Limited, is heartened by the response to the initiative, which was launched earlier this year.

“It’s fantastic to see such positive support from the dealer network and prospective delegates,” said Michael.

“To have six in the first cohort is terrific and going forward we will aim for no more than 10 so we retain that personal touch and hands-on, quality learning experience - they will support and learn from each other.

“It’s an exciting time for Kubota and Cambria, and we are delighted they are the first college we have worked with on the agricultural apprenticeship side. I’m sure this is the start of a great adventure together.”

Head of Llysfasi Iain Clarke added, "There has been a real buzz about it since the Scheme was launched in the Spring, and I’m confident that as it grows, we will see even more applications and help to meet demand for more skilled workers in the agricultural engineering industry.”

|  |

CROQUET COMPACTION RELIEVED

By Terrain Aeration in Shropshire

Company brought in to treat two croquet lawns that had been placed on a hard surface that, over time, had become so compacted, they developed severe waterlogging problems.

Terrain Aeration were recently brought in by the local council in Church Stretton, Shropshire, to treat two croquet lawns, that had been placed on a hard surface and, over time, had become so compacted, they developed severe waterlogging problems.

“We chose to go with Terrain because we needed to open up the ground for better drainage,” says Michael Turner, the council’s amenities and services officer, “and with the ground being so hard it needed breaking up very much deeper than normal aeration.”

Terrain Aeration carried out the work over one and a half days, with their Terralift machine’s JCB hammer slicing through the compaction to allow the hollow probe to reach up to a metre under the lawns. Working on a staggered grid pattern, once the probe reaches the optimum depth, compressed air is released up to a maximum of 20Bar (280psi). The blast effect fractures the compacted soil to allow drainage and deep aeration, with the grid ensuring each shot interconnects the fissures and fractures. As the probe withdraws, dried seaweed is injected which expands and contracts with the moisture content in the soil to keep the fissures open. The probe holes are then back-filled with Lytag, an inert product which allows air and water to percolate through but is mower friendly.

Michael added, “The whole process was very clean and professional and Terrain Aeration were nice people to work with. We’ve done a further piece of work with scarification and the combination of the two is bringing the results we wanted. We’re very happy with the work done.”

|

|

|  |

ADVERTISE YOUR JOBS HERE

Amazing success rates!

Advertise your recruitment needs on TurfPro Weekly Briefing and reach our targeted audience of recipients every week.

Contact Nikki Harrison for details - 01491 837117

|

|  |

|

|