TURF LIFE

. . a view from the dug-out

Not much info available so far, but a new turf machinery event was announced on Friday via the Twitter account @live_turf. ' Turf Maintenance Live' promises to showcase equipment from Blec Global, Ransomes Jacobsen, Rigby Taylor, Shelton Drainage and Wiedenmann UK on 12-13 May 10am-4pm, seemingly at Deeping Rangers FC, near Peterborough. The only other information given at this stage is the email address register@wiedenmann.co.uk and the tease of "Watch this space". Turf Maintenance Live' promises to showcase equipment from Blec Global, Ransomes Jacobsen, Rigby Taylor, Shelton Drainage and Wiedenmann UK on 12-13 May 10am-4pm, seemingly at Deeping Rangers FC, near Peterborough. The only other information given at this stage is the email address register@wiedenmann.co.uk and the tease of "Watch this space".

O2 have created a recycled smartphone, produced from grass clippings taken from the rugby pitch at Twickenham. Created in collaboration with designer Sean Miles, the ‘grass phone’ fully-functioning prototype is the UK’s first phone made from turf, report designboom.

Images courtesy of O2 Recycle

Supporting the RFU's new social responsibility program ‘Try For Change’, it aims to motivate people to recycle their old devices, by showing how aged technology has the potential to be upcycled into a new, original and unique product.

The manufacturing process took over 240 hours, combing tens of thousands of grass blades and locally-sourced wood for the buttons. the cuttings were freeze-dried before going through a pulping action and being molded into a template. once in the casing, the processed grass was covered in an eco-friendly resin, made from waste materials, hardening and bonding the clippings together in order to protect the inner mechanisms.

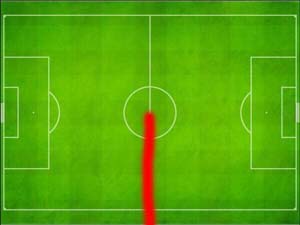

And excellent work from @footballtips yesterday. Steven Gerrard's heat map for his spectacular showing against Man Utd:

|