It has been a busy few days for industry trade press visits. As I reported in my blog last week, first there was a trip to see the new facility at the Howardson Group’s headquarters in Derby.

This was followed by some of the same trade press members coming together to view the latest investment by DLF, the Danish seed company, at its UK seed plant and trials site in Inkberrow, near Evesham, Worcestershire.

Sporting colours

A key investment here includes a £4.5 million Titan mixer plant, which increases capacity and reduces manual handling. Other developments have been the design and build of new showcase trail sites, including the construction of showcase natural grass sports playing surfaces where customers can come and see for themselves the quality and the performance of the many different DLF grass varieties that are now used in a variety of sports.

L-R: Tim and Derek

The event was held over two days with a warm welcome to the Inkberrow farm site that houses the seed cleaning, mixing, bagging and storage areas. We assembled in their brand-new training and meeting space. Derek Marriot- Smith was on hand to explain the activities we would be undertaking over the two days and introduced us to the company’s UK managing director, Tim Kerridge, who gave us an overview of the company’s history and the latest company strategies to ensure they can meet their customer’s everchanging needs.

Colour boost

He stated that the company’s core values are centred on the fact they work with nature and science to bring resilient seed solutions for land, life and people. These global values are the fundamental principles and beliefs that guide their actions and decisions, he said, and thereby creating the company’s culture.

He was keen to say that the growth of the business really took off with the acquisition of several other seed companies from the 1990s onwards, seeing the annual revenue growth in Euros grow substantially from 81m in 1990 to over 1000 m in 2024. This growth, he said, enables the company to invest and continue to fund its research programmes to further improve its products and services.

The DLF product range includes Johnson Sports Seed, MM, and Masterline brands, alongside seed and advanced seed coatings like Pro Nitro and Head Start Gold.

Derek Marriot-Smith putting on the golf green

The UK operation produces 14,500 tons of grass seed annually, with, according to Derek, a focus on sustainability and innovation. DLF's seed quality enhancements, including biostimulants like Grow Max, Head Start, and Pro Nitro, continue to enhance and improve seed performance under the many new climatic conditions ground practitioners and farmers now face arising from the current global rise in temperatures and ongoing changing weather patterns.

Disease pressures

Tim Kerridge was also keen to elaborate on the pressures of countries looking to reduce the reliance on pesticide products to maintain turf and crop health, which itself instigates the need to constantly continue to bring new products to market, in the form of disease resistant, drought tolerant and hard-wearing grasses.

Golf tee

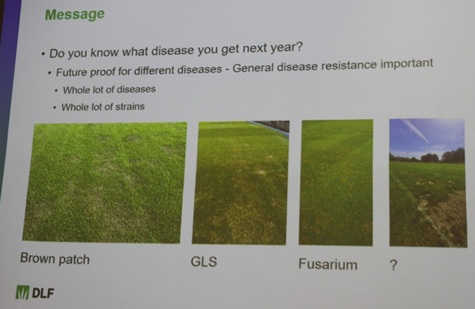

It is with this in mind that DLF are looking at finding sustainable solutions that focus on reducing chemical use and improving nitrogen efficiency. The new "Disease Watch" initiative aims to survey and address rapidly evolving diseases like brown patch, Gray leaf spot, and dollar spot - which are becoming major threats to turf quality. DLF's screening programs identify varieties with natural disease resistance, particularly tetraploids, to provide sustainable solutions. The company emphasises the importance of selecting varieties with higher natural disease tolerance to reduce chemical use and costs.

Derek flying the DLF flag

Derek then give us an update on the current sales staff covering the UK and Ireland and talk about the quality of the products they now produce and where some of them are being used.

Derek was also keen to mention the fact that DLF as part of the Disease Watch programme, will be asking practitioners and farmers to record and send in relevant data about the condition of their crops, and playing surfaces, so that data can be analysed to build up a map of trends / patterns of these disease outbreaks. Overtime may help them to have a better understanding of when and where these outbreaks are happening up and down the country.

Derek also talked about some major diseases that are becoming a serious problem in the UK. These being Brown Patch, Grey leaf spot, fusarium and dollar spot. The aim of the company is to get a better understanding of these diseases via their Disease Watch programme and over time come up with some new grass varieties that better resist the outbreaks of these prolific turf diseases.

He then introduced Paul Hadley, wildflower coordinator. Paul, like Derek, is a long serving member of the company and has a wealth of experience of the products the company produce. Paul’s role is to oversee the wildflower seed production, trials and develop new bespoke mixes for customers. He gave us an insight into the range of wildflower products that DLF produce and sell. The next day we got to view these as we were taken for a tour around the farm site, beginning with the seed cleaning, mixing and storage areas.

Titan bagging plant

The company’s investment in their bespoke Titan, 48 bin mixer, automated packing line and pneumatic closed self-cleaning system has increased productivity to 600 bags per hour, we were told, enabling the company to process, mix and bag seed much more efficiently with only three members of staff required to carry out these operations. Also helping is improved racking and storage areas and a fleet of electric fork lift trucks.

These improvements contribute to the fact that DLF UK can produce around 15,000 tonnes of seed annually, producing well over 1500 product lines, serving well over 2,500 customers.

Paul Hadley took the opportunity to introduce us to several of his staff who maintain and manage the production of wildflower seed. We viewed the small trial plots, the harvesting techniques (mostly done by hand) and the larger acreage plots that had been sown with knapweed. This crop is due to be harvested in August using their mini combine harvester.

Combine harvester

Finally, we had the chance to see their new unique showcase area, that provides the opportunity for customers to see at first hand the seed products used in the amenity and sports sectors. Sports turf contractor, Fine Turf were tasked with constructing several sports natural grass playing surfaces that included a golf tee, (sown with J Tee); Fairway (sown with MM22); and golf green (sown with J green / J all bent).

Cricket pitch

Also on site are a cricket pitch (sown with MM50); rugby and football pitch (sown with J premier 4Turf); a horse racing gallop (sown with MM tetrasport); tennis court (sown with MM50); and two ornamental lawns, one a hard wearing lawn (sown with PM50) and the other a fine lawn (J Fescue) turf.

Tennis court

Running either side of the gallop was several wildflower display, providing the opportunity to see the different colour mixes and pollinator and country seed mixes.

Horse gallop area with wildflowers either side

There is also a well-planted garden area that includes the ornamental lawns and seating area. Overall, I much say this was an impressive showcase area. All the sports areas are maintained by Matt Lewis, ex greenkeeper, whose job is to maintain the different playing surfaces, applying the relevant maintenance regimes to promote a healthy sward.

Matt Lewis mowing the fairway

I’d say he is certainly doing a good job considering they were only sown down in March. I was lucky enough to get some photographs of him mowing the football/ rugby pitch and golf surfaces using a Dennis FT cassette pedestrian mower and a Jacobsen ride-on triple mower.

Matt mowing with a triple mower

Matt is looking forward to seeing the site mature and become an important showcase for the DLF seed products.

Rugby / football pitch

Our tour of the DLF production site was an enlightening experience and I’m sure their new showcase area will be a popular attraction for visiting customers.

Editor Loz

I’d like to thank DLF for inviting me along to see the latest developments and investment that they are making to improve their seed production. As many of you may know, it usually takes several years of trials and testing procedures to bring new seed varieties to market. I am sure, as the years go by, this farm site and new showcase facility will allow future customers to see at first hand the production, performance and durability of their latest developments.