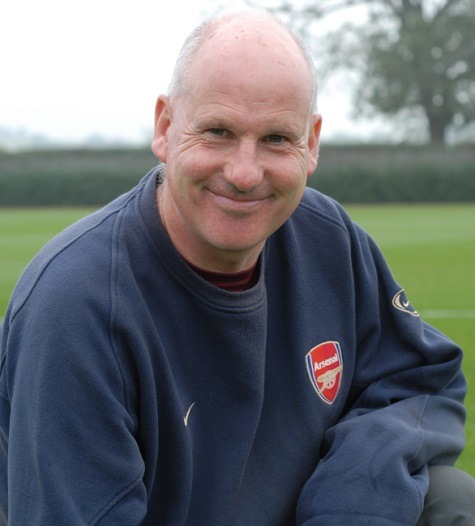

Before I get into this week's blog proper, I just want to say I was saddened to hear of the passing of Steve Braddock, Arsenal’s past head groundsman.

During his time at the club he revolutionised the way Premier League pitches are maintained. Utilising the latest technologies and best machinery, he transformed the way Arsenal’s stadium and training pitches were looked after.

Steve Braddock

He was looked upon as a pioneer, introducing many new techniques that he was prepared to share with other grounds professionals. He was in many people’s eyes a legend of our industry. I offer my sincere condolences to Steve’s family and friends.

I'd also like to take a moment to mention that James Mead, head of grounds at Rugby School, has retired with his deputy James Cavanagh taking over the reins. As mentioned in last week’s TurfPro blog, James and I started our careers together as parks apprentices 50 years ago this month with Birmingham City Council.

L-R James Mead and Mark Allen with the Webb Ellis Trophy at the Close Rugby School

James spent several years working for the council before he moved into a new job working for Kings Edward schools in 1983. He spent 15 years there, working his way up to the post of chief head of grounds, until 1997 when he moved into a new role as HG at Millfield School. He stayed there for eight years before finally taking his final job of head of grounds at Rugby School. He, like many leading lights of our industry, have brought many new ideas, innovations, and standards to the grounds sector.

During his time at the school, he has built up a formidable grounds team who between them have raised the standards of the schools’ facilities and without doubt now have some of the best school pitches in the country. 2023 sees the 200th year celebration of when William Webb Ellis started the game of rugby at Rugby School. One of James’ last projects was to oversee the redevelopment of this famous ruby pitch in the Close. Transforming it into a modern-day playing surface, fully drained, sand ameliorated and having a fully automated watering system, it’s a job that has just been completed by specialised contractors Agripower.

Current ground conditions

It’s the start of the rugby season, with clubs up and down the country venturing out onto the field of play once again.

However, I’m not sure I'd want to be playing rugby on any bone-hard rugby pitch across the land, with little or no grass cover. This summer’s extreme heat has burnt off and reduced grass growth to a minimum for most parts of the country, particularly in the southern areas of the UK.

Rugby match at Rugby School

Hopefully some of the recent rain showers may have helped with some recovery. Let’s also hope we can get some more rain in the coming weeks to initiate some proper regrowth while temperatures remain in double figures.

As a RFU Honda Rugby Grounds Connected voluntary pitch advisor, I would say it’s a good idea to get your pitches inspected - see here for information. There’s great advice and guidance to be had, plus a full report carried out and a 12 month return visit to check in. It really is a great free resource for rugby clubs.

End of season renovations

Top dressing with cricket loam

With the month of September fast approaching it’s also time cricket groundsmen started preparing and ordering their materials for their end of season renovations. Loam and seed will be much sort after, along with relevant contractors who carry out the work.

These end of season renovations are an essential requirement in getting your pitches into a good condition ready for next season. The aim of the renovations is to clear out all old surface debris, top dress with loam to relevel and provide a seed bed for germinating some new grass material that will help provide a safe and consistent playing surface for next season.

Key guide to successful renovations

All clubs have their own methods of working and renovating their squares. In most cases the level of work will be dictated by what budgets and resources they have available at the time, and what they are trying to achieve. Invest wisely and do not skimp on these renovations, it is important to remove all debris by scarifying in several directions and ensure you buy decent loan and seed.

Maintaining winter height of cut

Scarification is important to remove unwanted vegetation, but also to produce a key for the new loam material to sit in. The level of scarification required will be dependent on how much of a thatch layer you have generated throughout the season.

The square can then be over sown between 35-50 grammes per square metre. In essence, you are aiming to establish using a suitable grass seed mixture; do not be frightened to try out new cultivars.

It's important not to overdress the square, as you will not only be wasting the precious loam material, but you may also be smothering your sward. The last thing you want to be doing is to bury any vegetation, which will lead to future problems. The object of the renovations is to revitalise the top growing zone, restore levels and to integrate new material into the soil profile. This will help build up the clay content in your square.

Irrigation should follow as soon as possible to assist in the germination of new seed. By keeping the soil moist, the seed should germinate between 7-10 days weather permitting, a germination sheet will aid this process.

As for aerating the square this often happens later in the year when there is enough moisture content in the ground to allow the tines to penetrate to depth. Aeration relieves compaction and improves water percolation through the soil profile, but also helps to create the general environment essential for healthy grass growth. Autumn and winter aeration treatments are beneficial to promoting drier surfaces for further maintenance practices to take place.

Once the grass has germinated out on the square, you should look to maintain a cutting height between 15-25mm and continue to brush off the dew in the mornings to keep the sward in a dry and disease-free condition.