TurfPro editor Laurence Gale writes . . .

With cricket now being played, many groundsmen are mulling over the performance of their pitches. Terms are being used once again like slow and low, moist, a road, up and down, it will do a bit, pudding, I prepared a lovely loaf, scabby dog, crusty, shirt front, hint of green! All these comments are from practicing groundmen who are happy to share their thoughts on a communal cricket groundsman Facebook page.

Having spoken to many groundsmen over the years, the common theme is that even with years of experience and the fact they may have some preconceived idea out it may perform, it not really be until the game starts in earnest, that they see the fruits of their labour.

So what makes a good pitch? For many it is all about producing a pitch that makes a good game with something in it for both batsman and bowlers. They say a pitch that produces over 500 runs for both sides is a worthy pitch.

However, there are often too many variables that dictate the performance of the pitch. Weather being the main influence, along with the way the pitch has been prepared and maintained over time.

But as we all know, the quality of the pitch is heavily driven by the way we manage the underlying soils and grass sward we have inherited or nurtured over many years.

A recent conversation with David Goodjohn of Green Infrastructure Ltd enabled me to gauge his opinion on what is the best loam soil for cricket to be played on.

Cricket Loam

Some of the benefits of a having uniform soil texture and good soil structure are:

- High drainage rates

- Increased root development

- Surface able to withstand wear

- Positive air circulation - healthy microbial population

- Reduced incidence of disease

- Drier surface

A knowledge and understanding of soil physical properties has always been important for professional turf managers when making decisions about maintenance operations and when carrying out reconstruction works. Precise soil knowledge, including information on boundaries between soil types, should result in more efficient use of fertilisers, pesticides and improved management practices, thus ensuring that the final managed outputs result in the production of economically safe, consistent, playable natural sports turf surfaces.

Soils can vary in many ways, both physically and chemically, on a local or regional scale. Many factors, including original parent material source, climate, weathering processes, topography or history of the land use, influence their properties.

This soil variability gives rise to all the different types, universally classified by soil texture composition. Soil composition (soil texture) is determined predominantly by mineral particles and organic matter content and can be classified by the percentage of sand, silt and clay mineral particle content.

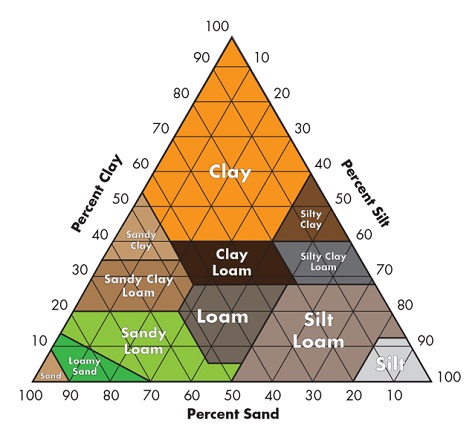

The Soil Texture Triangle, as shown on the above image, helps us classify the soil type. These percentages are determined by undertaking a PSD, particle size distribution analysis.

The definition of soil texture is the relative proportion of sand, silt or clay in a soil. The terms sand, silt, and clay refer to relative sizes of the soil particles - sand, being the larger soil particle, feels gritty; silt, being moderate in size, has a smooth or soapy texture; clay, being the smaller size feels sticky. Soil particles are illustrated in the table.

As cricketers and cricket groundsmen the term ‘cricket loam’ is often used, but what does it mean?

Loam is soil composed mostly of sand, silt, and a smaller amount of clay. By weight, its mineral composition is about 40–40–20% concentration of sand–silt–clay, respectively.

This is probably more of a gardener’s definition, so let’s define cricket loam (but let’s not forget tennis loam while we’re at it).

- SAND:-sediment whose particles are larger than silt (typically greater than 0.06 mm)

- SILT:- sediment whose particles are between clay and sand in size (typically 0.002–0.06 mm)

- CLAY:-sediment with particles smaller than silt, typically less than 0.002 mm

These are the technical definitions of the components of Loam, but inevitably as natural topsoils (or blends of soils) they will include an organic content – let’s say that ought to be under 5%

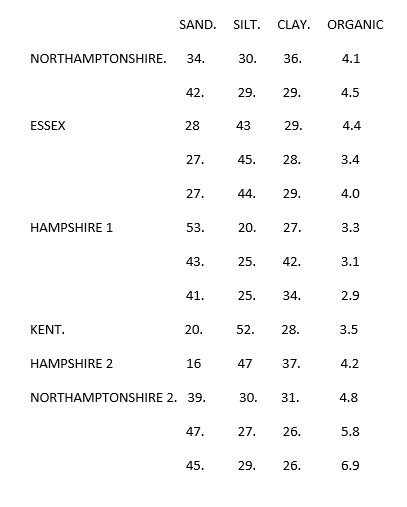

If we assume cricket loam stays the same (we’re always told not to change loams as they never ever alter not ever) let’s take a look at what options are available to us:

We haven’t touched on the products’ strength & shrinkage (we mention this later on in the compatability section), bulk density or chemical analysis (pH and so on) - but maybe that’s enough data for the time being.

(Geographical locations have been used to preserve the anonymity / intellectual property of the various manufacturers, but this is information many will not have seen in this tabulation in the past.)

You won’t find much of this info on the producers’ websites as loam is a closely guarded market prone to secrecy (hence the need for this blog). Brand names have been removed to save breaching copyrights and patents, but most of the important information is included in this tabulation. What relevance then do the numbers have to us as ground managers (Custodians of the Hallowed Turf)?

Most zero in on the CLAY CONTENT. Whilst this is important to indicate the kind of binding strength to expect from a product, it is not the sole factor we need to focus on. Higher clay content can INDICATE a high binding strength, but soil is complex so a combination of the sand, silt and clay with a lower clay and higher sand content CAN give a more resilient product. Particles interact, so the correct BALANCE is often superior to simply having a higher count in one or another category.

ORGANIC MATTER (OM) can often be as vital as simple clay content. If a loam has a high organic quotient, soil development over a period of time will produce humus and vegetative matter, both of which can contribute to an increase in OM. Inefficient or insufficient end of season renovation can be a major contributor to this menace to cricket squares.

Why do sand and silt matter? They don’t seem to contribute, do they? Incorrect once more my friend. We all have to bow to the maxim of BALANCE. It has been said in the past that the ‘perfect’ loam (for these usages) would be 33.33% each of sand, silt and clay but this rarely if ever occurs in nature.

Are these loams all natural products then? Very rarely would we be able to say this hand on heart as the bulk of loams for commercial sale are actually blends of different soils.

Should I always use a STERILISED Loam?

This is a bit of a misnomer which goes back to the olden (not necessarily golden) days of horticulture. Back then, gardeners preferred a sterilised loam into which they could pot their plants so that they didn’t encounter any pesky weeds. The sterilising process involved lots of nasty chemicals that quite simply ‘nuked’ the soil obliterating most of the natural goodness as well as the relatively few weed seeds lurking in the loam.

Nowadays the ‘sterilisimg’ process is not so much of a chemical blitzkrieg but much more of a simple ‘heat treatment’ whereby steam can be applied to the processed soils in a bid to eradicate weed seeds.

Does ‘sterilised’ (heat treated) loam do a better job than unsterilized?

That would depend on whether you choose to lose up to 90% of the goodness of your loam (microbes, beneficial humus etc.) in return for the possibility of removing a few percentage points of weed seeds. Loams are without exception produced, packaged and stored in a rural setting, so weed seeds can become incorporated simply by being blown in, so there is no such thing as a truly ‘sterilised’ loam. The choice is yours.

Am I right to think that a DIFFERENT Loam would not be compatible with my square?

Don’t ALWAYS believe someone who is selling a product to you, prove it to yourself! There is a very straightforward test called the Motty (or ASSB) Test that can help you with the evidence of your own eyes.

By a process of creating loam spheres of your own simply with soil and water, you can create a Motty of your own square material and one of the prospective loam. Different loams have different shrink and swell characteristics in that they swell more or less readily when they are wetted, and they shrink more or less readily as they dry. By dividing each soil medium in halves, introducing a slight ‘key’ to bind them together and then to combine them to be left to dry (naturally and gradually away from direct sunlight) you will see for yourself whether or not they separate through incompatibility. If there is little or no difference, the soils are unlikely to be incompatible so therefore you can make a choice on performance qualities instead of simply price or availability.

What is the PERFECT Loam then?

Quite often it can be the one you have been blessed with, that is the one you been managing for the last umpteen years. Clay content of a cricket loam typically accounts for around 25-35% of the loam.

For most cricket clubs we usually see the depth of loam ranging anything between 100-200mm.

The key to producing a good pitch is solely down to the management of this soil and the grass cover you maintain. Essentially the bulk density characteristics of the clay and how it is compacted during pitch preparation dictates the performance of the pitch in term of ball bounce and pace.

We must also remember the importance of carrying out end of season renovations, where you should be cleaning out (scarifying) any dead fibre material and top dressing with a compatible loam to restore levels and provide a seed bed for new grass seed.

My key message is to undertake an effective renovation programme at the end of the playing season to repair ends, restore levels and introduce some new grass seed into the square.

As most top professionals would say, skimp at your own peril, because if you do not carry out the appropriate level of work on your square it can lead to the production of inferior pitches the following season.

Again, the effectiveness of these renovations will be determined by the knowledge and resources available and no doubt governed by the current weather conditions to some degree. Aeration work may be a problem while the grounds remains dry and hard.

Also, if these conditions persist, you will need to keep any newly sown squares watered.

Renovating a square is hard work, often made harder if you do not have the appropriate machinery and personnel to undertake the work. There are some very good local contractors who are professionally geared up to undertake this work. It might be worthwhile obtaining a quote?

A visual examination of the surface is simply not good enough. Taking a number of core samples allows you to see the amount of thatch, root density and integrity of the soil, in terms of having any root breaks or changes of soil physical properties. Ideally you should be taking core samples to a depth between 100mm-150mm.

Also, the benefit of taking soil samples is you can send them off for a soil particle size analysis and nutrient status, thus giving you more information about your square.

It is important to order any materials in advance of the renovations. Seed and loam supplies can be delayed, get your order in early.