Having a sand-based pitch is now very much the norm in top professional sport, particularly football and rugby - whilst USGA sand-based golf greens have been around for 30 plus years.

The methodology advances in rootzone products has also grown with demand. We now see a range of reinforced rootzone options for natural turf pitches that include fibresand and fibre reinforced rootzones.

The common denominator in all these systems is sand - a very free draining medium that enables water to percolate through the profile of the rootzone very rapidly, generally specified to cope with between 25-40mm of rain per hour.

One company that has been instrumental in the development of these modern sand products is Mansfield Sand Company. A recent conversation with their golf and football sales manager Sharon Morris, gave me the opportunity to arrange a visit for both myself and Keith Kent, Twickenham’s head groundsman and Ted Mitchell the RFU facilities manager to see their headquarters and the new Two Oaks Quarry that replaced their Ratcher Hill quarry in October 2014.

Ted and Keith who are part of the RFU new Groundsmen Connect programme were keen to learn more about the sports turf products that can be used to help maintain and improve both natural and artificial rugby playing surfaces.

We could not have picked a better October day, the sun was shining, and we were met by Sharon and Gary Cunningham who introduced us to some of the company’s team, before taking us into the new quarry.

Keith Kent, Ted Mitchell and Laurence Gale

Mansfield Sand Company have been producing a range of sand-based products for the sports turf industry for many years. Operating from its long-established base in North Nottinghamshire, it has built up a solid, countrywide reputation as a specialist supplier of a comprehensive range of materials for the construction and maintenance of top-class sports and landscape surfaces.

Their core products include fibre reinforced rootzones (USGA rootzone and sand compost), top dressings, equestrian surfaces including Equs Elite and fibre sand equestrian, a wide range of silica sands, both dried and moist, industrial, pavior and foundry sands, asphalt sand, play pit sands, gravel and concrete brick and block products.

The aim of the tour was to catch up with the recent developments at the company following a successful opening of their brand-new quarry facility at Two Oaks Farm.

It took the company several years to find and carry out feasibility studies and gain planning permission for this new quarry. The permission includes planning conditions intended to control all aspects of the design, operation and restoration of the new quarry.

Mansfield Sand Company have invested several million pounds in the new quarry, making sure it has the latest washing and drying plants, machinery and conveyor systems to extract and process well over 300,000 tonnes of sand each year.

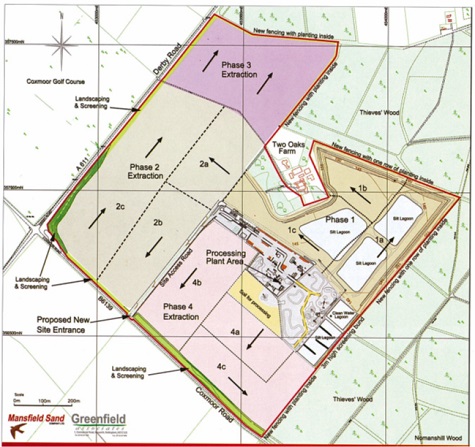

The new quarry is set in an area of around 100 hectares of agricultural land and the extraction area will be confined to 95 hectares. Progressive extraction of some 12million tonnes of saleable silica sand will take place in 4 phases over approximately 40 years. The sand will be excavated and transferred to the processing plant via a conveyor system. The unworked areas of the site will remain in agricultural use until required for mineral extraction.

As well as re-establishing high-quality agricultural land, progressive restoration will also create areas of lowland heathland, wet grassland - including reedbeds - and woodland, to increase the site biodiversity in line with the local Biodiversity Action Plan.

The Quarrying process will see four phases: -

Phase I: - Extraction will start next to the plant site working in a general northerly direction. Silt lagoons will be developed in the worked out areas. Progressive restoration will start on the upper parts of the Phase 1 faces.

Phase 2:- Extraction will move into Phase 2 in a generally southerly direction within the eastern section. Phase 2 will be subdivided into 3 working areas, moving generally southwards in the eastern sector and northwards next to the A61.

Phase 3:-Extraction will continue in a generally northerly direction and continue working through Phase 3. Partial restoration of Phase 2 will take place using soils from Phase 3.

Phase 4:-Soil stripped from Phase 4 will be used to complete the restoration of Phases 2 and 3, working in a generally southern/south easterly direction away from the processing plant.

Having donned the relevant PPE and been inducted to the site’s H&S policy, we were able to begin our quarry tour.

First port of call was the weighbridge where lorries are weighed both coming onto and going off the site, ensuring they are correctly loaded. Incoming unloaded lorries are also inspected by cameras for any signs of contamination and will not be filled until they are clean.

Next on the tour, was the chance to climb to the top of the drying plant’s six 200 tonne holding silos to get a bird’s eye view of the whole site. Here each of the sand quarrying processes could be both seen and explained.

The process starts with the Caterpillar Scraper which collects approximately 25 tonnes of the raw sand at a time. The Scraper then transports the sand to a hopper which feeds the conveyor belt system, taking the sand to the specialised hydro-classification washing plant (one of the most technically advanced in the industry). This complex washing process is designed to produce the tightly controlled specific grades of sand required and can cope with as much as 300 tonnes per hour.

Once washed the sand is moved about site by front end loaders to the next parts of the processes.

The washed sand can then be either delivered to the customer moist, fed into the sand drying plant or sent to the sports sands plant where it can be blended with any organics and fibres the customer may require. The plant has the ability to mix several different ratios of sand soil/compost rootzone products - 90/10, 85/15, 80/20, 75/25, 70/30, 60/40 and 50/50 and even sterilise sand/organic blends through another specialist rotary drier specifically designed to produce top dressing to a USGA standard.

Fibresand being loaded for a customer

In recent years, the company has also invested heavily in their sand bagging plant, which can bag products in various sizes, from 1 tonne bulk bags to 25kg to 12.5kg bagged sand products.

Sand and soil samples are tested daily for Particle Size Distribution (PSD), soil pH and organic matter (OM) content, with the aim of producing consistent materials for both the sports turf and landscaping industry. Every tonne of sand must be compatible and meet all the tolerances required for a sports sand specification.

Even in the supply of sands for top dressing of pitches, it is important that the products sold are tested. A robust testing procedure is in place with samples being taken at various times during the production process. These samples are then tested by the on-site laboratories, in order to meet any appropriate criteria.

Mansfield Sand is back in the game when it comes to the production and supply of Sterilised Top Dressings for mid-season fine turf application on rugby and football pitches, golf courses, bowling greens and domestic lawns. After a short absence from the market following relocation, production has now recommenced at the company’s flagship quarry at Two Oaks, Mansfield.

Easy to apply via any standard top-dressing spreading equipment, this quality-controlled mix is free draining and can be tailored to meet customers’ specific sporting surface requirements.

Delivery can be arranged via rigid bulk tippers of 10, 16 or 20-tonne net capacity; or 28/29 tonnes in articulated vehicles. Products are normally bagged in 1 tonne mini-bulk bags, palletised and shrink wrapped. Smaller 25kg bags are available to service the ad-hoc needs of smaller clubs and applications.

I would like to thank Mansfield Sand Company for allowing, myself, Keith and Ted the opportunity to see their facilities at first hand and giving a unique insight into how they produce such a fine range of sports sand materials that enable us to produce the fine playing surfaces we see today in professional and amateur sport.

It has taken years of planning and attention to detail for Mansfield to obtain a licence to extract these materials, and it is reassuring to know our industry now has a secured supply of quality materials for the next 40 years.

Personally, I would like to thank Mansfield sand for their invite and I know that both Keith and Ted enjoyed the opportunity to visit the quarry.

Keith Kent said, “I was most impressed with the whole environmental aspect. To have a 35 year plan for the site is simply amazing! The way that it was planned to work as an ongoing, moving quarry was amazing to hear.

“I was also impressed by the fact that no matter what question we asked it was answered straight away, no hesitation. John was so proud to tell us of how they had thought of everything we asked him. They know what they are doing and where they are going.

“The cleanliness of the whole site and the way that the H&S rules were implemented was outstanding. The technology used by the company was also very impressive.”