ENGAGING THE ENGAGERS

New machinery introduced to college lecturers

by Service Dealer Editor, Steve Gibbs

I attended an event at STIHL's HQ this week, which by introducing new machinery to college lecturers, was designed to ultimately instill a loyalty to their products amongst new, young users.

I was invited to STIHL GB’s headquarters in Camberley this week, for the first of what the manufacturer intends to be a series of events, designed to engage with college lecturers.

Entitled ‘Discovering STIHL’, representatives of land-based courses from educational establishments around the country were in attendance to learn what the manufacturer can offer their colleges and students. There were lecturers at Camberley for two days, from seats of learning including Sparsholt, Mysercough, Warwickshire, Newton Rigg, Shuttleworth, Writtle, and SRUC Oatridge - a real geographical spread. Importantly all the guys in attendance (and they were all men) had direct, student facing roles at their respective colleges.

STIHL's intention in introducing their company and products to this group, was to ultimately get their products in the hands of the young people coming through their courses. It was very much a brand awareness exercise. The company believes that if a young person picks up a chainsaw for the first time and it’s one of theirs, it’s quite likely that a bond will be formed with the brand. STIHL is hoping that students who graduate, having been exposed to their products during their learning period, once they are out in the workplace, or in their own lives, they will be entering dealerships with very specific knowledge and desires for certain products.

I suppose the effect that STIHL is hoping for is similar to the feeling of loyalty or fondness people can have towards the make of car that they learned to drive in.

The event was shaped around a day at STIHL HQ based in the training room plus tours around the facilities, followed by a day out at Merrist Wood college, with an opportunity to get hands on with a selection of the latest equipment.

STIHL product trainer, Tom Eadie, who was running the course alongside product training team manager, Ben Beaumont and technical trainer, Mark Helliwell, explained why the company felt now was a perfect time to be talking to these lecturers.

“We’re hearing that a lot of the technical information out there in some colleges, can be something like 20 years out of date,” he said. “We want to make sure that these guys are fully informed about the latest machinery and techniques which are available to them and their students.”

As this was the first event of this type, STIHL were always very keen to receive feedback from the lecturers that the days were delivering the information most useful to them. As such, one of the first tasks of day one was for the lecturers to write down a subject they specifically wanted to hear about. Interestingly, most either mentioned diagnostics or future products, with several listing battery technology as an area of interest.

Before new products and technologies were explored in detail though, to give the lecturers in attendance a flavour of how STIHL GB works, tours were given around the offices and the huge warehouse in Camberley. A sense of scale of the operation was conveyed, witnessing the vast array of products being readied to be distributed to dealers around the UK.

The significant portion of Day 1 though, was taking the lecturers through some real deep dives on latest products and technologies. As requested, a significant period was taken up with demonstrations of the latest computerised diagnostic systems which the company can offer. Mark Helewell went into great detail about the working of company’s M-Tronic system verses conventional technology. There was high engagement with questions on best practice and maintenance techniques. Mark explained the online diagnostic tools which the company offers that the colleges can have access to.

Tom Eadie and Ben Beaumont then introduced several new products, some of which are not available in dealerships quite yet. More than just a series of sales pitches, these introductions were detailed technical workshops really. Breaking the machines down into their component parts, the lecturers were able to ask in-depth questions of the product specialists, to really get a sense of what new developments could be available to their students.

Machines considered included the BR 800 backpack blower; MS 462 and MS 500i chainsaws; the MSA 220 C and MSA 161T cordless saws and the new AR 200L & 300L backpack batteries. Alongside these, considerable interest was generated in the explanation of the new STIHL Connect digital tracking system.

What these sessions also engendered was a dialogue, both between the colleges and STIHL, but also between the representatives of the different educational establishments themselves. These were knowledgeable guys, who knew their machinery, swapping ideas and getting into serious conversations about where the industry is heading and what part manufacturers, and significantly, dealers will play in that.

After all the theory, Day 2 saw everyone bussed out to Merrist Wood to test the machines discussed in the classroom, in a practical setting. Mowers, chainsaws, blowers, all were thoroughly put through their paces, by experts in positions to act as significant influencers of up-coming users.

All in all, Discovering STIHL was a well organised, timely and detailed event. I certainly got the impression that the lecturers in attendance were engaged and given plenty of valuable information which they will be able to pass on to their students

Eventually this bank of knowledge should find its way back through the doors of your dealerships, in the guise of the next generation of informed customers.

The college lecturers group with the STIHL trainers at Merrist Wood on Wednesday this week

|

|

|  |

BRIGGS & STRATTON POST "DISAPPOINTING" Q4 & FULL YEAR RESULTS

Q4 5.9% down, full year 2.4% down

The fourth quarter of 2019 capped a difficult year of "unprecedented market challenges and higher than expected operational inefficiencies" says CEO.

Briggs & Stratton Corporation in the U.S has announced financial results for its fiscal fourth quarter and year ended June 30, 2019 - describing them as "disappointing".

The company released the following analysis -

For the fiscal 2019 fourth quarter:

- Fiscal fourth quarter net sales were $472 million, a decrease of $30 million or 5.9% from $502 million for the prior year. Fiscal 2018's fourth quarter included approximately $20 million of accelerated sales in anticipation of the go-live of the company's upgraded ERP system at the beginning of fiscal 2019. Adjusting for this, net sales this year decreased approximately 2%. Shipments for the fiscal 2019 fourth quarter fell short of expectations primarily due to difficult market conditions caused by an unusually wet spring in North America compounded by near-term market disruptions caused by channel partner transitions.

- Quarterly GAAP gross profit margin of 14.4% and adjusted gross profit margin of 15.0% decreased from gross profit margin of 21.7% and adjusted gross profit margin of 22.1% last year due to sales mix, lower production volumes and operational inefficiencies. Challenges in labour availability restricted the Company's ability to more quickly remediate start-up inefficiencies related to the business optimisation initiatives.

- Fourth quarter GAAP net loss of $18.5 million, or $0.45 per share, included business optimisation charges, acquisition integration charges and a pension settlement charge. Excluding these items, adjusted net loss was $14.9 million, or $0.36 per share, as compared to adjusted net income of $0.47 per diluted share for the fourth quarter of fiscal 2018. The fourth quarter of fiscal 2019 also included a non-cash tax related charge of $5.1 million, or $0.12 per share.

For the fiscal 2019 full year:

- Fiscal 2019 net sales were $1.84 billion, down $44.7 million or 2.4% from $1.88 billion for fiscal 2018 primarily due to unusually dry weather conditions in Australia and Europe, lower storm generator sales and lower service parts sales, and near-term disruption caused by channel partner transitions, including the bankruptcy of a major North American retailer. Sales of commercial engines and products increased approximately 13% for the fiscal year.

- Full-year GAAP gross profit margin of 16.4% was down from 21.2% for fiscal 2018. Adjusted gross profit margin of 17.0% was down from 21.5% last year due to sales mix, lower production volumes and startup inefficiencies from the Company's business optimisation initiatives.

- Full-year GAAP net loss of $54.1 million, or $1.31 per share, included business optimisation charges, bad debt expense for a major retailer that filed for bankruptcy protection, a litigation settlement charge, a pension settlement charge, senior note repurchase premiums, a tax charge associated with tax reform and integration charges. Excluding these items, adjusted net loss was $12.9 million, or $0.32 per share.

Todd J. Teske, Chairman, President and Chief Executive Officer said, "We are clearly disappointed with the fiscal 2019 results. The fourth quarter capped a difficult year of unprecedented market challenges and higher than expected operational inefficiencies encountered during the ramp-up of our business optimisation initiatives.

"The North America lawn and garden market slowed considerably as the quarter progressed from unusually wet, cool spring weather compounded by near-term market disruptions with channel partners. Europe set record high temperatures in June and July to impede channel inventory reductions. While we achieved operational improvements on many of the business optimisation program start-up issues, continued inefficiencies offset the benefit of those improvements, including near-term labour availability challenges."

Teske continued, "Regardless of the cause of the various headwinds, it is our responsibility to address the issues and restore the company to growth and profitability. As we enter fiscal 2020, we are intensely focused on five key areas to drive improvements in performance:

- First, we are working aggressively to complete the business optimisation program and eliminate the operational inefficiencies to begin realizing the $35 million to $40 million in pre-tax cost savings from the program.

- Second, as we have also announced, we will be consolidating engine production within our plant in Poplar Bluff, Missouri, to streamline operations and adjust production capacity to meet current and anticipated future needs. This initiative will reduce pre-tax expenses by up to $14 million when fully implemented.

- Third, we will be devoting increased time and focus to more fully analysing the dynamics of our market with outside help to position our business for more sustained growth and higher returns. Gaining an outside perspective will help our thinking, planning and actions to further adapt to the continually changing environment so that we are properly positioned as the market continues to change.

- Fourth, we intend to strengthen our balance sheet, with the near-term objectives of improving working capital and lowering debt. With the winding down of investments in our business optimisation initiatives, projected lower capital expenditures and the action announced today to reduce the cash dividend, we will be directing more funds to reduce debt and invest in attractive commercial products and enabling technologies.

- Fifth, we are making solid progress on a debt refinancing which we expect to close before the end of our first fiscal quarter. We believe the refinancing will provide good flexibility as we strengthen the balance sheet and execute our strategy."

Teske concluded, "There is no question that fiscal 2019 was enormously difficult from both a market perspective and our execution on operational excellence. Still, the several foundational changes we implemented advanced our commercial growth and diversification strategy and position us well for the long term. We remain confident in our strategy and view fiscal 2020 as an opportunity to get back on track."

In terms of the 2020 outlook the company says net sales are expected to be within a range of $1.91 billion to $1.97 billion for fiscal 2020, which contemplates midpoint growth of approximately 5.5% over fiscal 2019's performance.

This outlook compares with the company's previous preliminary expectation of approximately $2.01 billion in sales for fiscal 2020.

The revision to the outlook principally relates to the lower base sales for fiscal 2019, a reduction in the company's estimate of the North American market due to near-term disruption caused by channel partner transitions and the prolonged impact of weather on Europe, which has experienced hot and dry conditions in the early months of summer

|  |

SMALL ENGINE PRODUCTION TO BE 'CONSOLIDATED'

Briggs & Stratton closing factory in Kentucky

Following the news of the 'disappointing' results, manufacturer will shift production of its small vertical-shaft engines into its Poplar Bluff, Missouri facility.

Following on from their "disappointing" Q4 and year end results, Briggs & Stratton Corporation in the U.S announced plans to consolidate production of its small vertical-shaft engines into its Poplar Bluff, Missouri facility.

This consolidation will result in the closure of the company's Murray, Kentucky facility by the autumn of 2020 with the company saying this is intended to align production capacity with current and expected future market needs.

In an official statement, Briggs and Stratton said, "The market for small vertical-shaft engines has been relatively stable over the last several years but has not grown for various reasons, including a difficult housing market driven by the lack of affordable single-family homes in the United States.

"Unlike other areas of Briggs & Stratton's business such as commercial engines and products which have seen double-digit growth, the residential walk-behind mower market, where the vast majority of these engines are used, has not rebounded to historical levels. Accordingly, the Company is taking action to right-size its footprint."

Todd Teske, Chairman, President & CEO of Briggs & Stratton Corporation added, "Our residential engine business continues to be core to our company as we make progress on diversifying our business by growing our commercial presence. This production consolidation is important for the long-term health of this operation and will allow for better utilisation of our assets by freeing up resources that we can use on growth areas within our company.

"Our team in Murray has done great things over the three decades since the plant was established. We are grateful for their work and the support we have received from the local community and Commonwealth of Kentucky."

It was reported that impacted employees will have the opportunity to relocate to another facility. The Poplar Bluff plant will be hiring to accommodate the increased production being added to that facility, in addition to the hiring taking place within the company's commercial businesses.

The Company anticipates annualised pre-tax savings of $12 million to $14 million, with approximately $10 million recognised by fiscal year 2021. Total charges related to the consolidation are expected to total $30 million to $35 million over fiscal years 2020 and 2021.

|  |

JOHN DEERE QUARTERLY SALES DOWN 3%

Net income of $899 million in Q3

This week's WEB ONLY story is the company in the U,S says the results reflect the high degree of uncertainty that continues to overshadow the agricultural sector.

STOLEN MOWERS RECOVERED

Hustlers found

The two Hustler mowers and a trailer which we reported that Southern Machinery had stolen last week, have been recovered by Derbyshire Constabulary.

You may remember last week that Philip Tutty of Southern Machinery had been in touch to inform us that the company had suffered a theft of two Hustler Zero Turn Lawnmowers and a 14ft Ifor Williams from the hard shoulder of the A50 near to Derby.

Hustler mowers similar to these were stolen

We are pleased to report this week that Philp has been back in touch to let us know that everything has now been found.

Philip said, "I'm delighted to report that Derbyshire Constabulary have recovered our two Hustler Zero Turn Lawnmowers and trailer safe and well.

"We are deeply indebted to them for their quick action and top class police work."

FAROL SUPPLY 'RECORD BEATING' 51 GATORS

To event equipment supply company

Energy Generator Hire Limited, based in Aylesbury, has recently added the John Deere vehicles to its UK hire fleet, which marks the largest single order for Gators in the UK.

Event equipment supply company Energy Generator Hire Limited, based in Aylesbury, Buckinghamshire, has recently added a record beating 51 John Deere Gator 4x4 utility vehicles to its UK hire fleet, which now numbers in excess of 170 units.

A drone shot of the new 51-strong John Deere Gator fleet taken at dealer Farol’s Milton Common headquarters

Supplied by Farol Limited of Milton Common near Thame in Oxfordshire and supported by John Deere Financial, the purchase of the XUV 855D two-seater models was already the largest single order for Gators in the UK, before they were joined shortly afterwards by another 12 S4 four-seater versions to keep up with customer demand.

Energy Generator Hire was established in 2004 with just one generator by owner and managing director Tom Carr, who identified a market opportunity to offer a one stop shop, full turnkey service to the events industry.

The company now specialises in short, medium and long term hire of power and generation equipment to various industry sectors, including events, construction, motor racing and, in the near future, the equestrian market. Energy will also be venturing into the electric vehicles sector in line with its sustainability and environmental policies.

“I was always intrigued by the events industry, and initially concentrated on temporary power supply services,” says Tom. "On visiting customer venues more frequently, we soon realised that all-terrain vehicles were also in great demand, and so expansion of The Energy Group began naturally from there.”

Energy bought its first John Deere Gator in 2015, initially for use at the company’s premises, but it wasn’t long before enquiries for the vehicle started flooding in. Due to Energy’s longstanding relationship with Farol area sales manager John Bennetts and John Deere Financial, the Gator fleet has increased rapidly due to a mix of repeat custom and new business.

“When you delve into a new aspect of any business, market and product research are key,” says Tom. “We studied all types of machine in the ATV market, and after gaining feedback from our clients, particularly festival organisers, it was John Deere who stood out as the number one choice.

“The new Gators were ordered with full specification to ensure they meet all our customers’ needs, delivering a premium product to stand alongside our first-rate service. They are fast becoming the industry standard and are more often than not requested by the end user due to their reliability and durability.

“We’ve found that the John Deere Gator can handle all kinds of terrain with ease, and due to their high specification they can also be used safely and efficiently 24 hours a day by our ever-expanding client base, both indoors if required as well as outdoors. In addition, all of our hire vehicles are Trackered and barcoded, not only for security but also to ensure fleet management and logistics are streamlined.

“This is vital, considering that the company’s entire machinery fleet now numbers more than 500 units. Add to this the fully comprehensive and strict maintenance schedule entrusted to Farol, and we can offer complete peace of mind to our clients countrywide.”

Energy Generator Hire’s owner Tom Carr (right) with Farol’s John Bennetts at the handover of the new John Deere Gator utility vehicles

John Deere Financial area sales manager Christophe Verteneuil says, “This deal was the perfect example of consulting with a valued client to ensure the best available package was structured to suit both our lending criteria and the customer’s needs.

“Primarily, to manage a transaction of this scale, we arranged a credit line after gaining an understanding of Tom’s business challenges and opportunities. Flexibility was key, from identifying the most suitable financial product to being adaptable with regards to the payment schedule, which we were able to match to the seasonal cashflow of the business.”

Tom Carr adds: “Residual value is also very important when undertaking an investment of this magnitude. John Deere Gators, when serviced and maintained correctly, hold their market value well and this is extremely beneficial when renewing our fleet.”

|  |

IAN CAMPBELL JOINS GGM GROUNDSCARE

Ex Sisis and Campey man

GGM Groundscare have expanded their sales operation with the appointment of Ian Campbell as business development manager.

GGM Groundscare have expanded their sales operation with the appointment of Ian Campbell as business development manager.

Ian Campbell (left) is welcomed to the GGM Groundscare team by Chris Gibson

Ian, who joins GGM having previously worked initially at Sisis and latterly at Campey Turf Care, will be working alongside the rest of the GGM team to develop the sales of Kubota, Baroness, Dennis & Sisis & Amazone and GGM’s other groundscare franchises.

GGM say Ian’s appointment demonstrates their ongoing commitment of building an ever growing team capable of exceeding customer expectations and delivering first class sales, hire and service support across the North West of England and Yorkshire.

Chris Gibson, managing director of GGM Groundscare said, “Ian brings with him over 38 years experience within groundscare including extensive experience within the sports turf sector coupled with a wealth of knowledge and a great amount of enthusiasm. He is a fantastic addition to our team and he joins us with substantial selling and account management experience within similar markets and I’m sure he will thrive in his new role.”

Ian says of his new role, "I’m excited and very much looking forward to getting out and meeting customers and demonstrating the fantastic capabilities and benefits of our range of machinery”.

|  |

GSK PRAISES ELMO*

*Electronic Lawn Mowing Operative

British multinational pharmaceutical company, GlaxoSmithKline (GSK), has praised the adoption of Husqvarna Automower technology to maintain the green spaces around its Global head office in Brentford.

British multinational pharmaceutical company, GlaxoSmithKline (GSK), has praised the adoption of Husqvarna Automower technology to maintain the green spaces around its Global head office in Brentford over the past three years.

The robotic mower at work at GlaxoSmithKline's head office

GSK house in Brentford has relied on ELMO, a robotic lawnmower manufactured by Husqvarna and named by GSK staff, to work unassisted and maintain a large lawn area surrounding its headquarters.

ELMO stands for Electronic Lawn Mowing Operative and is an Automower which is able to maintain green spaces up to 5000m2 per machine. Installed in 2017 by Sodexo, GSK’s grounds maintenance provider, the company say the robotic mower has quietly gone about its business and without disturbing office staff, cutting little and often through its random mowing pattern, ensuring that grass of GSK house remains a lush, healthy green.

Sodexo’s senior facilities service manager for GSK, Michelle Chapman, said, “ELMO has truly become part of the family at GSK house – our staff just love watching the robot work and GSK couldn’t be without ELMO now.

“For us, the Automower means time saved and an environmentally way for us to manage the green spaces at our headquarters whilst improving the lawn appearance. It gives the grounds team more time to focus on other, more crucial things and the fact that it’s silent in its working means it does not disturb staff when cutting the grass.”

UK Manager - Husqvarna Professional, Kevin Ashmore, commented, “Sodexo’s close relationship with Husqvarna was key in them being one of the first in the UK to trial Husqvarna Automower in public spaces. The result was that GSK Brentwood recommended the Husqvarna Automower to many of its main Global sites.”

|  |

CLAYDON APPOINT NEW DEALER

Collings Brothers of Abbotsley

Claydon Drills has further expanded its UK distribution network with the appointment of an additional dealer with two branches in the East of England.

Claydon Drills has further expanded its UK distribution network with the appointment of an additional dealer with two branches in the East of England.

A Claydon Hybrid T4 drill working behind a Case IH Puma 185 tractor

Collings Brothers of Abbotsley has been in the agricultural engineering business since the company was founded in 1930. Well-known and highly respected, it operates from depots at Abbotsley near St Neots and Brigstock near Kettering which serve customers in Cambridgeshire, Bedfordshire, Northamptonshire and the surrounding areas. Both will sell and service the full range of Claydon Opti-Till products.

“We are very excited to have taken on the Claydon franchise at a time when reducing crop establishment costs is becoming essential for any farming business,” said Jason Weston, sales and after sales care manager for Collings Brothers.

Rob Dunk, Claydon Drills’ sales manager for the UK and Ireland added, "This appointment is part of our strategy to develop the potential of the Claydon Opti-Till range by increasing sales through existing dealers and making additional appointments in areas where we are not currently represented."

|  |

PETER LEECH & GRAHAM DALE SET FOR 1000 MILE CHARITY DRIVE

In aid of Prostate Cancer UK

Ex John Deere and Lely men are taking part in The Round Britain Coastal Drive.

Well known industry figures, Peter Leech and Graham Dale, are set to drive over 1000 miles to raise awareness and funds for Prostate Cancer UK.

Peter Leech

They will be taking part in the Round Britain Coastal Drive (RBCD) which is organised by the XK Club for owners of Jaguar XK cars.

Peter said, "Graham and I will driving the first 6 stages totalling approximately 1000 miles in a 60 year old XK150."

Graham Dale

Graham and Peter are both retired members of the Land based Engineering Industry. Graham was managing Director of Lely UK who were also the Toro commercial distributor for the UK and Peter was a senior executive of John Deere Ltd. Both have strong industry links with the AEA, IAgrE and BAGMA having held various roles including Graham as a past president of the AEA and Peter as a past president of IAgrE.

You can donate to Peter and Graham's cause by visiting their Just Giving page.

|

|  |

ADVERTISE YOUR JOBS HERE

Amazing success rates!

Advertise your recruitment needs on Serivce Dealer Weekly Update and reach our targeted audience of recipients every week.

Contact Nikki Harrison for details - 01491 837117

|

|  |

Sending Quality Customers To Dealers

Full dealer listing for just 26p per day

|

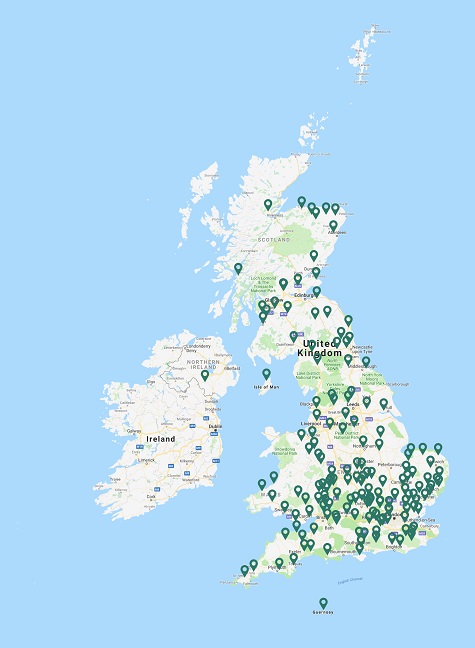

Garden Trader is designed to specifically identify and catch customers when they are researching a product online and helping them locate their local dealer. We know this because we invest several thousand pounds every month to reach them through highly targeted keyword and PPC activity. It is important that customers understand the true value of product knowledge and customer service provided by our amazing dealer network. Garden Trader is delivering on average 550 potential customers every year to individual dealer's pages. Because of the site promotional criteria, we know the majority are actively looking to make a purchase (product or service). All subscribed dealers can easily check their listing's analytics just by logging in to see for themselves just how Garden Trader is helping their business. At 26p per day, we don't believe any other form of highly targeted digital promotion can get anywhere close to this value. Better still, it was designed to promote our highly skilled dealer network in the UK and helping fight discount based zero value online retailers and DIY stores. If you do wish to re-subscribe or indeed register it is easy and takes just a few minutes.

Garden Trader is a product and dealer search website/directory only for specialist garden machinery dealers in the UK. It has been designed to support and promote our dealer industry to consumers who are specifically searching for garden machinery products and services.

It is easy and quick to register and costs just £96 + VAT per year to be listed and all revenues in 2019 will be reinvested into promoting the site online.

Garden Trader

Join the country’s only independent specialist website, created by the team that bring you Service Dealer. Join our subscribed Garden Trader dealers now by clicking on “Register Dealership” and let's fight back against the zero value retailers.

Map of dealerships registered with Garden Trader

FIND OUT MORE

|

|  |

LATEST SHOWS & EXHIBITIONS

Sponsored by STIHL GB

|

|

|