ROBOTS AND ZEROS

Burgeoning product sectors?

by Service Dealer Editor, Steve Gibbs

With reports of decent robotic sales this year and the news that AriensCo is going to build zero-turns in Britain for the domestic market, are dealers finding increasing success with these machinery categories?

What a week!

Keeping on top of all the toings and froings at Westminster (not to mention keeping check on whether Steve Smith is out yet!) has proved really quite exhausting.

I’m grateful therefore that in this climate I edit a journal about outdoor powered machinery. Clearly our industry will be greatly affected by the B-word, which ever road it ends up developing down - but frankly it'll be delightful when we return to mostly worrying about the weather!

Which correct me if I’m wrong, hasn’t proved to be all that bad for dealers just recently? I've been hearing various, cautiously optimistic, reports.

For example, I spoke to one supplier this week who was very enthusiastic about the way the season has panned out for their company. They were telling me that in particular, they had seen great success with robotic mowers.

As well as a general upturn in the acceptance of the machines, they were saying that certain customers with large areas to take care of, are now seeing the benefits of having multiple robots out cutting.

Once it’s been broken down in terms of how much it costs to cut per square metre, and how individuals can then be deployed elsewhere to carry on with more skilled work, this supplier was telling me, that customers are starting to consider the usage of robots as a "no-brainer". Surely this isn't a phrase which would've have been used around the products just a few years ago?

So is this a school of thought which is being seen in customers with expanses to cut across the country? Robotic manufacturers will certainly claim their usage is becoming ever more common, but have they truly crossed over into mainstream customer acceptance?

Back in February, we speculated on whether 2019 was panning out to be the year of the robot? Now we’re deeper into the season, do we think this is a fair assessment of their rise in popularity? Or is it a tad hyperbolic? Are we at the stage where if a customer has a grand or two burning a hole in their pocket for a new mower, ride-ons might face some seriously stiff competition?

It would be interesting to hear from our readers today, just how robots have been performing for your business lately.

We have some other positive news today coming out of Great Haseley regarding AriensCo's decision to start producing zero-turn mowers in Britain. This is an exciting development both in terms of the jobs which will be created, but also in terms of the confidence which the manufacturer is showing in zero-turns for this side of the Atlantic.

Received opinion has traditionally suggested that zero-turns are not a product which does that well over here. The machines are often thought of as a peculiarly American tool. But AriensCo must clearly believe that is changing.

I remember speaking to David Withers several years ago at a BTME exhibition, when he was still based in the States with Ransomes, about the differences in popularity between zero-turns over there and over here. At that point Ransomes had bought Dixie Chopper, with the mowers a significant part of their business in the States - but there was no real push of the machines in UK.

At that point David had a couple of theories as to why they had struggled to make a mark this country. One major factor which he believed had hampered their uptake, was simply due to not enough homeowners having a big enough plot of land that requires cutting that quickly. This is a fundamental difference in the market compared to the amount of large homesteads in the U.S. Another was that the units can't be driven down the road to the next job.

He did however believe that within 10 years the machines would have a significant presence in the UK due to more productive, less-expensive products usually winning out.

Well, we're not quite at that predicted 10 year point today, but are you seeing an increase in the machines' popularity in your dealerships? Are customers looking for zero-turns to perform certain tasks, meaning AriensCo confidence is justified?

It would be great to hear what our readers think. Please let us know your thoughts in the comments below.

|

|

|  |

ARIENSCO TO MANUFACTURE ZERO TURNS IN BRITAIN

At factory in Great Haseley, Oxfordshire

Production of Ariens brand zero-turn mowers believed to be the first zero-turns to be manufactured in Europe.

AriensCo has announced that production of Ariens brand zero-turn mowers will commence at the company’s factory in Great Haseley, Oxfordshire.

It’s believed these will be the first zero-turns to be manufactured in Europe.

AriensCo reports seeing an exceptional growth in demand for zero-turn mowers in the UK and Europe. This follows similar trends in the US, where they say sales have more than tripled since 2003 as the popularity among users has soared.

In an official statement, AriensCo said, "According to industry analysis, zero-turn sales in Europe have grown more than 30% over the last four years, making them the fastest growing category of ride-on mowers and third fastest in the lawn and garden power equipment sector."

Darren Spencer, Vice President - EMEA and Asia added, “Sales of zero-turns in Europe have experienced exceptional growth over the past three years.

“AriensCo have experienced this growth in numerous markets and, based upon extensive research with our distribution partners, we expect the growth to continue. This industry analysis points to the many opportunities to be met by producing zero-turns at our Great Haseley plant. We currently sell into ten different countries within Europe and aim to increase our European footprint in 2020. Future growth will accelerate as the benefits of zero-turn mowers are understood by customers. Zero-turn users are experiencing increased speed of cut and greater versatility over tractors and out-fronts.”

During 2019 AriensCo say they continue to make significant investment in the Oxfordshire factory in preparation for zero-turn production, including a new production line, fixtures and tooling. The UK will be manufacturing CE zero-turns for European markets only and will initially be producing the IKON, APEX and ZENITH models. Close collaboration with the US will be maintained to ensure products match up to Ariens’ reputation for manufacturing quality.

Zero-turn production in the UK is seen to offer significant advantages, allowing for rapid delivery and improved availability throughout the year. There is also potential for zero-turns to be adapted with features and benefits to meet local market needs. Increased utilisation of the manufacturing facility at Great Haseley will provide operational cost benefits and will generate a number of new jobs for the area.

The first zero-turn to come off the production line will be at the end of October.

|  |

STIGA GROUP APPOINTS NEW CHIEF EXECUTIVE OFFICER

Georg Metz steps down after 10 years

Englishman, Sean Robinson, becomes CEO, having held leadership positions in businesses operating across a variety of industries in countries across the world.

Stiga SpA have announced that its Board of Directors has appointed Sean Robinson as new CEO of the Stiga Group.

Sean Robinson

Previous incumbent, Georg Metz, has stepped down, deciding after 10 years leading the company and spending more than 40 years in the industry, to now devote more time to his family and to other commercial and private tasks.

In addition it has been announced that Sean will be appointed Chairman of the Board of Directors of Stiga SpA and Executive Director of Stiga C and Stiga S.A. boards.

Laurence Raven, Chairman of the Board of the Stiga Group, said, “For 10 years Georg has been an outstanding leader of our business. On behalf of everyone at Stiga I would like to place on record my profound gratitude for everything that Georg has done for the company during his tenure as CEO. His vision, drive and deep personal commitment to Stiga has delivered a transformation in the company’s fortunes.

"He leaves a company that is more agile and resilient, and in an excellent position to succeed in an increasingly fast-changing and dynamic industry. Georg has every reason to be proud of what he has accomplished and we wish him every happiness and success for the future."

Laurence Raven continued, “I am absolutely delighted that Sean has agreed to become the new CEO of the Group. Sean brings a wealth of experience to the role, having held leadership positions in businesses operating across a variety of industries in many countries all over the world.

"Since he joined Stiga in January of this year he has developed a deep understanding of our business and the industry. In recent months he has also made a significant contribution to the development of Stiga’s long term business strategy as the company embraces the evolutionary change taking place in the markets in which we operate. The Board looks forward to working with Sean as we progress towards the delivery of this strategy and is highly confident that under his leadership, Stiga will prosper long into the

future."

Sean is native English, but his professional life has taken him around the globe as a senior executive manager who has held many important roles in a variety of high-level managerial positions within leading international companies.

After an initial experience at BAE Systems and another at Case, he moved to Bosch where he held a Director position between 1998 and 2002. Then he joined Dyson, where he started as Manufacturing Director for UK and Malaysia and was eventually appointed Managing Director in 2007. In 2010 he joined HYVA, a major international player

in transportation/trucking/railroad solutions, as Chief Operating Officer based in Hong Kong, being in charge of group strategy, operations, supply chain, service, product development, and quality and brand management.

Finally in 2015 he joined Fischer & Paykel Appliances, an international player in modern home appliances and part of the global Haier Group, where he was based in the New Zealand HQ. There he was the CEO of the Technology Group, responsible for driving the growth and development of the business with success in Asia, Europe and North America.

|  |

NEW HOLLAND UNVEIL LOW CARBON TRACTOR

At Low Carbon Vehicle Event this week

This week's WEB ONLY story is that the first pre-development of the project, which aims to design a commercially viable tractor capable of operation on biomethane while complying with the latest emissions standards, was shown in Millbrook, Bedfordshire.

LISTER WILDER TEAMS UP WITH PREDATOR

Appointed as a main dealer

Dealer to offer a comprehensive supply and servicing network, across a wide area of southern England, for the range of tree stump grinders.

Lister Wilder has been appointed as a main dealer for the Predator range of tree stump grinders, offering a comprehensive supply and servicing network across a wide area of southern England.

Based near Henley-on-Thames in Oxfordshire, Predator supply narrow-access grinders with a range extending from portable machinery through to radio-controlled tracked vehicles.

Lister Wilder say the Predator machinery fits well into their Groundcare & Arb Division, which operates from branches in Wallingford, Reading, Cirencester, Ashford, Devizes and Bristol. Each has highly equipped mobile servicing teams and parts back-up to support its sales experts. Reading-based Lee Hatton will act as brand champion for Predator.

Lister Wilder Groundcare sales director Phill Hughes says he's delighted to add Predator to the company’s brand portfolio. “Predator has a big reputation for well-designed and reliable grinders that suit the often difficult access conditions in the UK,” he says. “We already have a very successful relationship with Timberwolf in the chipper sector, so this is a very good addition for us.”

|  |

CLAYDON DRILLS FURTHER EXPAND DEALER NETWORK

Appointment for the Midlands

Sharmans Agricultural Limited is the latest dealer for the range of direct strip seeding crop establishment technology.

Claydon Drills, the direct strip seeding crop establishment technology manufacturer, has further expanded its UK dealer distribution network in the Midlands by appointing Sharmans Agricultural Limited.

Sharmans is a family-run agricultural machinery dealership which has expanded progressively since coming under the guidance of the Barclay family in 1981.

Duncan Hood, group sales manager, Sharmans Agriculture Ltd

The company’s head office at Gonerby Moor near Grantham in Lincolnshire is complemented by four other branches, at Easton on the Hill near Stamford in Lincolnshire, Melton Mowbray in Leicestershire, Lowdham in Nottinghamshire and Pytchley in Northamptonshire. All except Pytchley will sell and service the full range of Claydon Opti-Till products.

“Sharmans only takes on new product lines after considerable consideration, investigation and preparation, but having done so commits fully to developing their potential,” Duncan Hood, Group Sales Manager states. “We are therefore delighted to be working closely with Claydon Drills, another family-run, customer-focused company with an excellent reputation.”

Rob Dunk, Claydon Drills’ sales manager for the UK and Ireland, said, “The appointment of Sharmans Agricultural Limited is another key step in expanding our UK dealer network, This will ensure that existing owners of Claydon products in these areas and customers who are new to our brand benefit from first-class sales and service support."

|  |

ABREY REACH ZIEGLER LANDMARK

100 sales in 2019

Abrey Agricultural Ltd say they have reached a significant landmark this year, notching up 100 sales of Ziegler header trailers.

Abrey Agricultural Ltd say they have reached a significant landmark this year, notching up 100 sales of Ziegler header trailers.

Ziegler’s range includes a four-wheel steer trailer that the company say is selling strongly in the UK, particularly to farmers who have to negotiate narrow gateways, awkward road corners and tight farmyard accesses.

Toby Abrey says he believes the trailers could help users gain a number of important practical and agronomic benefits.

“Enabling the combine to tow and manoeuvre the header efficiently may transform what had previously been a job that needed two people and machines into a one-person operation, releasing staff and tractors for other tasks, which could be crucial during a busy harvest.

“As well as making it easier and quicker to move harvesting equipment around, that extra manoeuvrability might enable some farmers to considering investing in a bigger combine or wider header.

“That could increase their harvesting capacity and speed, which could help reduce both their labour costs and the risk of being disrupted by the weather”.

|  |

DEALER PRAISES BUSINESS COACH

MKM Agri supported by Fourmative

Specialst ATV / UTV dealers MKM Agri have praised the business support they have received from business coaching and mentoring company, Fourmative.

Specialst ATV / UTV dealers MKM Agri have praised the business support they have received from business coaching and mentoring company, Fourmative.

MKM Agri

Established for 25 years, MKM are the only 4-brand ATV/UTV specialists in the UK and run by Mark and Anthony Deacon, a father and son relationship that has seen successive years of growth and profitability from their head office in Bedford and new Suffolk branch.

Their management team is supported by Colin Gleghorn from Fourmative who provides on-site support to the owners. MKM say Colin helps with writing business plans and budgets, staff appraisals and new appointments, measuring department sales and profitability plus looking at marketing strategy.

Anthony Deacon said, "I have engaged with Colin for over two years and my team see him as a trusted business ally and confidant. Using his years’ of business management experience helps us make more of the right decisions quicker and with real confidence."

Colin from Fourmative added, "It is not unusual for Mark or Anthony to ring me late at night with an idea or business question for me to ponder and reply the next day. The relationship is built on trust and direct, frank replies. If I like the idea I’ll tell them, if I don’t like it, I’ll them that too!. Helping to quantify their success and guiding them on best practice is my personal driver. Moving them on towards achieving the business potential is why I visit them every month."

|  |

LEMKEN EXTEND AFTER SALES SUPPORT

Offline spare parts catalogue and update stick now available

Lemken have announced they have extended their after sales support for dealers with the release of an offline spare parts catalogue and an update stick.

Lemken have announced they have extended their after sales support for dealers with the release of an offline spare parts catalogue and an update stick.

Lemken Update Stick with CCI-50 terminal

The company say that dealers have already enjoyed permanent online access to all product information since last year. The LEONIS information portal additionally provides dealers with exclusive access to spare parts lists, implement data, training documentation and the latest news. This range of services has now been expanded with the release of the offline spare parts catalogue and an update stick.

With LEONIS, LEMKENDOC and the update stick, Lemken says it offers its partners a powerful package of three components to support repairs and ensure that farmers enjoy high implement availability. The Lemken after-sales support package is available worldwide.

The company says the new LEMKENDOC spare parts catalogue provides up-to-date access to original spare parts catalogues at any time. Spare parts can be identified anywhere at any time and then ordered online later. An integrated search for spare parts by serial number and a customisable notes function complement this service, says Lemken, to cut down on the number of enquiries needed and avoid mistakes when ordering.

The company additionally provides its partners with an update stick, which allows service technicians to perform software updates on implements and terminals. The update stick connects regularly to the Lemken software pool and therefore always contains the latest software versions. Technicians also have access to older versions and are able to reset implements to their original settings via a backup and restore function.

|  |

KUHN OFFERING GERMANY TOUR

With fertiliser spreader purchase

Customers purchasing an Axis 40.2 EMC or 50.2 EMC in early September 2019 could receive an all-expenses-paid trip to Germany with Kuhn Farm Machinery.

Customers purchasing an Axis 40.2 EMC or 50.2 EMC fertiliser spreader in early September 2019 could receive an all-expenses-paid trip to Germany with Kuhn Farm Machinery.

Axis fertiliser spreader

The company is offering the trip, which will include a visit to Rauch’s new state-of-the-art spreader testing facility in Rheinmünster, near Baden Baden, to the first 20 customers from 1st September, to mark the 20th anniversary of Electronic Mass Control (EMC) technology.

Initially only available on hydraulic drive Axis spreaders, but now also a feature on mechanical drive machines, the EMC system works by constantly monitoring fertiliser flow (every second). The company says it enables almost instantaneous adjustment of speedservo/aperture positions to either side of the machine in response to changes in fertiliser flow-ability (as may be caused by a partial blockage for example). Similarly, as application rate is a function of forward speed, disc speed and working width, any changes to these parameters are managed by the machine’s information system to allow almost instantaneous adjustment on the move and the maintenance of the target application rate.

Farmers or contractors ordering an Axis 40.2 or Axis 50.2 fertiliser spreader from 1st September are advised to check with their KUHN dealer if they have qualified for the trip to Germany. Full details of the trip, which will be scheduled for spring 2020, will be available through KUHN dealerships.

|

|

|  |

ADVERTISE YOUR JOBS HERE

Amazing success rates!

Advertise your recruitment needs on Serivce Dealer Weekly Update and reach our targeted audience of recipients every week.

Contact Nikki Harrison for details - 01491 837117

|

|  |

HUSQVARNA LAUNCHES AUTOMOWER® FAIRWAY KIT FOR OPTIMUM ROBOTIC MOWER PERFORMANCE

On golf courses & other sports turf applications

The new kit lowers the cutting height of Husqvarna Automower® to a minimum of approximately 10mm whilst also providing new cutting height steps of 12.5mm, 15mm and 17.5mm.

Husqvarna has introduced a new robotic mower fairway kit designed to be used on golf fairways and other sports turf applications. The new kit lowers the cutting height of Husqvarna Automower® to a minimum of approximately 10mm whilst also providing new cutting height steps of 12.5mm, 15mm and 17.5mm. The standard cutting height on all Husqvarna Automower® models excluding the AWD models is 20mm.

The kit ensures that the lower cutting heights required on areas such as fairways can be achieved using a Husqvarna robotic mower. The combination of Husqvarna Automower® and the new kit allows areas such as fairways to be maintained at a constant length throughout the year, creating consistency in the playing conditions experienced by golfers. The ultra-silent mowers are also extremely unobtrusive ensuring that players are not disturbed and also allows night time operation.

The use of robotic mowers on large and labour intensive areas of grass which require regular maintenance also allows the redeployment of grounds staff on to more skilled tasks. The robotic mowers are designed to cut little and often recycling the micro-clippings back into the soil improving grass quality whilst maintaining a consistent grass length throughout the growing season.

Worcestershire Golf Club are amongst a growing number of golf courses utilising Husqvarna Automower® as part of course maintenance. Steve Lloyd, Course Manager commented "It’s great because it means we can keep a consistent cut throughout the week. It also saves us time on a large area, allowing the team to focus on hard to reach and trickier areas. One of the best things is how the micro-clippings fertilise the grass. The quality of the grass has improved massively in a very short space of time".

The kits are designed to be used on the following Automower® models : 420, 430X, 450X, 520 and 550.

Husqvarna Automower® fairway kit includes:

• Spacers - 10mm and 12.5mm (only one to be used)

• New cutting disc

• Fasteners

• Lid

• NOTE: Due to the lower cutting height the skid plate should not be used.

The fairway kit is available to order and has an RRP of £25.00 inc. VAT

For further information on the Husqvarna Automower® fairway kit and the rest of the Husqvarna Automower® range, please visit: www.husqvarna.com/uk/roboticmowers or contact your local Husqvarna area business manager.

www.husqvarna.com/uk

|  |

REGISTER FOR SALTEX 2019

Now open

Registration for Europe’s largest annual groundscare exhibition SALTEX 2019 is now open and visitors will notice some notable improvements to the registration process.

Registration for Europe’s largest annual groundscare exhibition SALTEX 2019 is now open and visitors will notice some notable improvements to the registration process.

Visitor registration is an integral part of the customer journey and new for SALTEX 2019 event organisers have partnered with LiveBuzz – the largest registration specialist in the UK which is the preferred supplier for some of the world’s most prestigious events.

SALTEX 2019 registration opens this month

Commenting on the new registration partnership, SALTEX event director Matthew Knight said: “It’s important that our visitors, our exhibitors and their customers have the best possible experience at SALTEX. We are always aiming to make improvements to the show each year and following an open tendering process we appointed LiveBuzz because we want the very best in all aspects of the show.

“We are confident that our visitors will experience a best practice registration process – it will be smoother, more interactive and in addition there will be ten registration terminals at the show entrance meaning that visitors will gain faster entry.”

Taking place at the NEC, Birmingham on 30 and 31 October, SALTEX 2019 will feature over 300 exhibitors including some of the biggest names in groundscare. The two-day event will offer visitors a unique opportunity to experience the very latest industry trends and innovations, enhance their education and learn from industry experts.

The exhibition is the longest-standing event of its kind in the world, having been held almost every year since 1938, and the show is continually evolving with the people of the industry in mind.

This year the show floor will be bursting with everything a visitor needs to increase their efficiency and improve operations – and attendees can expect features such as:

- NEW! Eco Village – live demonstrations purely dedicated to environmentally-friendly products.

- Learning LIVE - SALTEX’s world-class free educational programme.

- Pathology and Soil Science LIVE – a look in detail at the symptoms of turfgrass fungal disease problems.

- SALTEX Innovation Award – celebrating the very best in new groundscare technology.

- Ask the Expert - free face-to-face turfcare advice.

- Outdoor Demonstrations – the latest products in action in an area directly outside halls 6,7 and 8.

- SALTEX College Cup - land based colleges compete in an academic test of turf management knowledge.

- Lawn Care Legends LIVE – a fantastic networking opportunity for landscapers and gardeners.

- Job Clinic – free one-to-one sessions covering CV writing to interview techniques.

Registration is accessible through the SALTEX website and visitors can simply bring their email confirmation (on a phone or a printed copy to the registration desk) which will be located at the show entrance.

SALTEX 2019 takes place at the NEC, Birmingham on October 30 and 31.

For more information visit www.iogsaltex.com

Follow SALTEX on Twitter @IOG_SALTEX and Facebook – www.facebook.com/IOGSALTEX

|  |

Sending Quality Customers To Dealers

Full dealer listing for just 26p per day

|

Garden Trader is designed to specifically identify and catch customers when they are researching a product online and helping them locate their local dealer. We know this because we invest several thousand pounds every month to reach them through highly targeted keyword and PPC activity. It is important that customers understand the true value of product knowledge and customer service provided by our amazing dealer network. Garden Trader is delivering on average 550 potential customers every year to individual dealer's pages. Because of the site promotional criteria, we know the majority are actively looking to make a purchase (product or service). All subscribed dealers can easily check their listing's analytics just by logging in to see for themselves just how Garden Trader is helping their business. At 26p per day, we don't believe any other form of highly targeted digital promotion can get anywhere close to this value. Better still, it was designed to promote our highly skilled dealer network in the UK and helping fight discount based zero value online retailers and DIY stores. If you do wish to re-subscribe or indeed register it is easy and takes just a few minutes.

Garden Trader is a product and dealer search website/directory only for specialist garden machinery dealers in the UK. It has been designed to support and promote our dealer industry to consumers who are specifically searching for garden machinery products and services.

It is easy and quick to register and costs just £96 + VAT per year to be listed and all revenues in 2019 will be reinvested into promoting the site online.

Garden Trader

Join the country’s only independent specialist website, created by the team that bring you Service Dealer. Join our subscribed Garden Trader dealers now by clicking on “Register Dealership” and let's fight back against the zero value retailers.

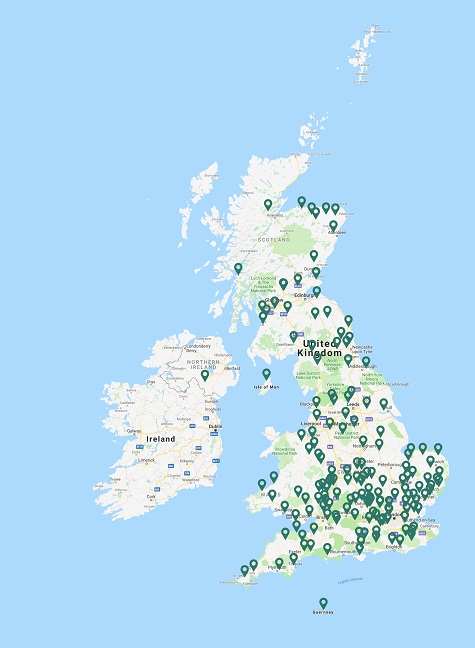

Map of dealerships registered with Garden Trader

FIND OUT MORE

|

|  |

LATEST SHOWS & EXHIBITIONS

Sponsored by STIHL GB

|

|  |

|  |

|  |

|  |

|  |

FAMILY VALUES

Reflections on the Ernest Doe takeover of Bartram Mowers

by Chris Biddle, Service Dealer Founder

It is always sad when a well-known name disappears from the industry front-line.

It is always sad when a well-known name disappears from the industry front-line.

Such is the case with Bartram Mowers, acquired last week by Ernest Doe following Ransomes decision to remove the franchise from the Norwich-based turfcare dealer and distributor. It is understood that Ransomes business accounted for almost a third of Bartram’s turnover so no amount of future business modelling would have realistically made up that shortfall, particularly in the current climate.

There is a certain satisfaction that a long-established family firm has been taken over by another long-established family firm. Established in 1898 as a blacksmith business, Doe’s have the bragging rights on longevity, with both companies getting seriously involved in the grass machinery business in the early 1970s. This was the start of the ‘heydays’ for the mower business that was to last for 20 years or so. The ‘sheds’ were in their infancy, local authorities had spending power (and spent to protect budgets whether they needed new kit or not) – and Tim Berners Lee was still a decade away from creating the internet.

The early days were notable for the amount of large scale distributors supplying the trade, a number of whom bit the dust when the DIY superstores started to take lumps out of the dealers’ traditional business during the 1990s.

The major sheds had taken over the light mains electric business, and companies (who were often major Flymo distributors) such as Stanley West in the South West and A M Russell in Scotland, folded as the volume business disappeared. Flymo themselves had owned their own dealer/distributor in Cheshire Light Tractors, later to morph into Cheshire Turf Machinery.

Bartram responded by being one of the first dealers to embrace the internet by setting up LawnmowersDirect in 1999 to bolster its consumer business (which stoked up lively comment from a number of fellow dealers!) and started expanding its professional turfcare business.

There is a fascinating dynamic in the relationship between big corporations and family businesses in this industry. In recent years, corporations like John Deere and Textron (Ransomes) have moved into appointing ‘super dealerships’ covering large territories with a multi-branch network. Their driving force is business efficiencies and the protection of shareholder values. They look at the market in calculated terms, but we are not yet in the realms of manufacturer-owned dealerships as in the car trade.

This industry is far too fragmented for that to be feasible – and single franchise dealerships have never really worked. Inevitably, when multi-nationals meet family businesses, their priorities are invariably different. Yes, potential and profitability are key factors, but equally so – people. People in a family business are rarely regarded as expendable commodities. They are the central core and fabric of family business. The protection of jobs will have weighed heavily in any decision taken by Bartram and Doe, and I understand a good number have been employed by Ernest Doe at the two branches (North Walsham and Framlingham) responsible for the additional business.

L-R: Colin Doe and Mark Bartram

So what now for Bartrams? Outline planning permission to develop the +20 acre Bluebell Road site has been in place for a few years, and recently retirement home specialist McCarthy and Stone announced plans to build 32 bungalows and 22 apartments on the site. Nonetheless it will be an obvious wrench for the Bartram family to exit the business that has been their focus for almost 48 years.

Of course it begs the question as ‘super-dealerships’ expand, will they start to exert extra pressure on manufacturers? The sheds dictated their terms to suppliers in the 1990s in a way that smaller retailers could never hope to achieve. And that changed the way that machines were sold into retail. Flexibility and ‘one-stop’ distributors emerged, largely at the expense of stock-orders and advance bulk ordering from manufacturers by dealers.

So, we wish the Ernest Doe team well in the expansion of their business, and say thank you to the Bartram family for their considerable influence in the garden machinery ‘biz’ over many years.

We should be proud that strong family concerns, large and small, are still the backbone of our industry, not hedge fund managers or venture capitalists.

Perhaps we are just not that interesting!

|

|

|  |

DOES BATTERY POWER REALLY SAVE ON C02 EMISSIONS?

d

FAMILY VALUES

Reflections on the Ernest Doe takeover of Bartram Mowers

by Chris Biddle, Service Dealer Founder

It is always sad when a well-known name disappears from the industry front-line.

It is always sad when a well-known name disappears from the industry front-line.

Such is the case with Bartram Mowers, acquired last week by Ernest Doe following Ransomes decision to remove the franchise from the Norwich-based turfcare dealer and distributor. It is understood that Ransomes business accounted for almost a third of Bartram’s turnover so no amount of future business modelling would have realistically made up that shortfall, particularly in the current climate.

There is a certain satisfaction that a long-established family firm has been taken over by another long-established family firm. Established in 1898 as a blacksmith business, Doe’s have the bragging rights on longevity, with both companies getting seriously involved in the grass machinery business in the early 1970s. This was the start of the ‘heydays’ for the mower business that was to last for 20 years or so. The ‘sheds’ were in their infancy, local authorities had spending power (and spent to protect budgets whether they needed new kit or not) – and Tim Berners Lee was still a decade away from creating the internet.

The early days were notable for the amount of large scale distributors supplying the trade, a number of whom bit the dust when the DIY superstores started to take lumps out of the dealers’ traditional business during the 1990s.

The major sheds had taken over the light mains electric business, and companies (who were often major Flymo distributors) such as Stanley West in the South West and A M Russell in Scotland, folded as the volume business disappeared. Flymo themselves had owned their own dealer/distributor in Cheshire Light Tractors, later to morph into Cheshire Turf Machinery. Bartram responded by being one of the first dealers to embrace the internet by setting up LawnmowersDirect in 1999 to bolster its consumer business (which stoked up comment from a number of fellow dealers!) and started expanding its professional turfcare business.

There is a fascinating dynamic in the relationship between big corporations and family businesses in this industry. In recent years, corporations like John Deere and Textron (Ransomes) have moved into appointing ‘super dealerships’ covering large territories with a multi-branch network. Their driving force is business efficiencies and the protection of shareholder values. They look at the market in calculated terms, but we are not yet in the realms of manufacture-owned dealerships as in the car trade.

This industry is far too fragmented for that to be feasible – and single franchise dealerships have never really worked. Inevitably, when multi-nationals meet family businesses, their priorities are invariably different. Yes, potential and profitability are key factors, but equally so – people. People in a family business are rarely regarded as expendable commodities. They are the central core and fabric of family business. The protection of jobs will have weighed heavily in any decision taken by Bartram, and I understand a good number have been employed by Ernest Doe at the two branches (North Walsham and Framlingham) responsible for the additional business.

L-R: Colin Doe and Mark Bartram

So what now for Bartrams? Outline planning permission to develop the +20 acre Bluebell Road site has been in place for a few years, and recently retirement home specialist McCarthy and Stone announced plans to build 32 bungalows and 22 apartments on the site. Nonetheless it will be an obvious wrench for the Bartram family to exit the business that has been their focus for almost 48 years.

Of course it begs the question as ‘super-dealerships’ expand, will they start to exert extra pressure on manufacturers? The sheds dictated their terms to suppliers in the 1990s in a way that smaller retailers could never hope to achieve. And that changed the way that machines were sold into retail. Flexibility and ‘one-stop’ distributors emerged at the expense of stock-orders and advance bulk ordering by dealers.

So, we wish the Ernest Doe team well in the expansion of their business, and say thank you to the Bartram family for their considerable influence in the garden machinery ‘biz’ over many years. We should be proud that strong family concerns, large and small, are still the backbone of our industry, not hedge fund managers or venture capitalists. Perhaps we are just not that interesting!

|

|

|

|