DECLINE IN FERTILISER USAGE

Teagasc National Farm Survey results

by Service Dealer Ireland Editor, Liam de Paor

Survey studied trends in fertiliser use by nitrates zone, land use class, farm system, stocking rate and agri-environmental scheme participation.

Teagasc did a National Farm Survey on fertiliser use for 2005-2015. It detailed the average quantities of Nitrogen (N), Phosphorus (P) and Potassium (K) macro-nutrients and lime applied at farm level and the types of fertiliser used on grassland & tillage farms.

Trends in fertiliser use by nitrates zone, land use class, farm system, stocking rate and agri-environmental scheme participation were studied. Unfortunately the survey shows that there was a serious decline in the usage of fertilisers and only around 20% of farmers were using lime year-on-year.

Taking into account the increasing numbers of dairy cows, and a fodder crisis in 2018 there is an urgent need to increase and optimise the use of fertilisers and lime.

In 2010, we had just over one million dairy cows in the Republic of Ireland and in 2017 – we have about 1.4 million cows.

N application rates on grazing area were highest in 2005 at 82 kg ha-1, before declining by 15-30% to 57-70 kg ha-1 from 2008 to 2012.

P application rates on grazing area were also highest in 2005 (7 kg ha-1), before declining by 43-57% to 3-4 kg ha-1 between 2008 and 2012 and increasing again to 5 kg ha-1 by 2015..

K application rates were highest in 2005 at 15 kg ha-1, before declining by 47-60% from 2008 to 2012.

Higher application rates of N, P and K were generally associated with farms in nitrates zone A (South and East of the country), farms of wide land use potential, dairy farms and with higher stocking rates.

There was significant volatility in N application rates on silage area, with the lowest and highest application rates recorded in 2008 (96 kg ha-1) and 2013 (121 kg ha-1) respectively. The 2013 recovery was as a result of the poor weather in 2012 and resultant fodder crisis.

P application rates on silage ground were highest at the start and end of the study period (11-12 kg ha-1) but declined by between 25-42% to 7-9 kg ha-1 during the years 2008 to 10.

Overall, K application rates ranged from 17-25 kg ha-1, with the highest application rates in 2005 (25 kg ha-1) and the lowest in 2008 (17 kg ha-1).

N application rates on the main cereal crops (wheat, barley and oats) were highest at 158 kg ha-1 in 2015. This was 10% higher than starting period levels and nearly 20% higher than the low in 2008 of 133 kg ha-1.

P application rates on cereals were broadly similar at the start and end of the study period (25-27 kg ha-1) having dipped by 30% (18-19 kg ha-1) in 2009/2010.

K application rates were at a high of 80 kg ha-1 in 2015 up from 60 kg ha-1 in 2005. N application rates were 11 highest on winter crops.

Application rates of P over the study period were highest on winter and spring barley at 26 and 24 kg ha-1 respectively.

Average K application rates were highest across winter crops, with winter wheat and barley having similar average applications rates over the study period at 77 kg ha-1 followed by oats at 69 kg ha-1.

On average just over 20% of farms were using lime year-on-year over the study period. The lowest rate was in 2006 at 16% and the highest in 2013 at 26% of total farms. Higher rates were associated with farms of wide land use potential, dairy farms and higher stocking rates.

With high fertiliser costs it is vital that the correct rate is applied evenly, advises Dermot Forristal of the Teagasc.

If the incorrect rate is applied, grass or crop yield is lost or fertiliser is wasted, and crop or grass quality can be reduced. In cereals, crop lodging causes greater losses. Variations within the spreading width mean some of the crop gets too little, some too much.

Uneven spreading is obvious if green striping is seen in the crop or grass, but losses are also incurred at lower levels of unevenness where no striping is visible.

The cost of inaccurate spreading is difficult to estimate could be up to €80/ha so the increasing use of GPS system for precision application of crop nutrients is very welcome trend indeed.

These GPS equipped fertiliser spreaders are usually only available from agri contractors who are now using large machines for bulk spreading of fertilisers.

The use of a large machine is also making better use of scarce and expensive labour as farm contractors find it ever more difficult to source suitable machinery operators.

|

|

|  |

MCHALE BROTHERS AWARDED

FTMTA Gold medal

Brothers Padraic and Martin McHale received the FTMTA Gold Award from Minister for Agriculture Michael Creed at the recent FTMTA farm machinery show.

Periodically the FTMTA executive council presents a gold award to a person who has given a long or outstanding service to the association or the agricultural machinery industry. This award is open to all working FTMTA member firms and its staff.

Brothers Padraic and Martin McHale received FTMTA Gold Award from Minister for Agriculture Michael Creed and FTMTA Chief Executive Gary Ryan and President Jimmy Butler at the recent FMTA farm machinery show.

The award presentation was pictured on McHale's Facebook page

McHale Engineering was founded by Padraic and Martin McHale in the mid-1980s.Before he started manufacturing, Padraic sold used tractors and machinery from 1976.He was later joined by his younger brother Martin.

Coming from a farming background and the sales experience gained from farmer and contactors was a valuable asset to their manufacturing business. In the early days Padraic looked after product design and manufacturing while Martin looked after sales and marketing.

Grass crops are heavier and wetter in Ireland than in most other countries so this impacts heavily on forage machinery designed for lighter and drier crops found in Britain and elsewhere.

The McHale brothers knew this, valued feedback from their customers and designed their machinery to cope with the more difficult Irish weather. This in turn ensured a longer working and trouble free life for their machinery on other more benign markets.

Their first machine manufactured in 1982 was a Silage Block cutter which they tested on their own home farm while improving it. This was followed by a range of slurry pumping equipment.

In 1987, the McHale brothers manufactured their first round bale wrapper. Martin travelled to Britain to develop a dealer network which now numbers 70 dealers, many of whom have been with McHale for over 30 years. Outside of Britain, one of the first exports markets targeted was Australia in 1994.

The grass season in Australia started in August or September each year when the European season was coming to a close so they could keep their factory busy all year round. Nowadays their best markets also include New Zealand, South Korea, Japan, China, South Africa and Chile.”

In 1995, McHale’s participated at the Agritechnica Show and secured new distributors across Europe. McHale achieved ISO certification for its quality standards in 1997. Over the years they have also received awards for export and performance including the AIB export award and the Wang export company award.

By 1999, McHale was exporting machinery to 25 countries and they relocated their manufacturing plant to a 20ac Greenfield site in Ballinrobe, building a 100,000 square foot manufacturing premises. Since then the plant has expanded and is now 320,000 square feet (8ac of roofed area).

In 2005 the McHale design team received the prestigious Royal Agricultural Society of England’s (RASE) Gold Medal award at the Royal Show for their Fusion bale wrapper. The judges chose the McHale Fusion Integrated Baler Wrapper for its economy of operation, compact dimensions, its ability to work well on sloping land, high output and the company reputation.

In 2009, McHale launched the V660 variable chamber or belt baler which was designed for drier climates and where there was demand for larger bales. Due to its success, in 2007 a non-chopper baler, the F540, and a fully automatic baler, the F560, were also added to the range.

The Fusion 3 Plus was launched in 2013 and the Innovative film binding results in better silage quality and easier to feed out bales. In 2015 McHale moved into the mower market with their Pro Glide front, rear and combination mowers.

At the 2017 Irish Ploughing Championships McHale unveiled two models in its centre delivery rake range – the R62-72 & R68-78.Today, McHale is one of the largest employers in Co. Mayo, with exports accounting for 90% of sales. Their machinery can be seen working around the world in 55 countries.

|  |

OVER 20,000 ATTEND FTMTA FARM MACHINERY SHOW

Similar numbers to previous show

According to Gary Ryan, CEO of the FTMTA around 20,500 farmers and agri contractors visited the 2019 event in Punchestown.

According to Gary Ryan, CEO of the FTMTA around 20,500 farmers and agri contractors visited the 2019 Farm Machinery Show in Punchestown - which was a similar attendance for the previous show in 2017.

Gary said, “Feedback from the trade exhibitors and visitors has been very good - possibly the best I can remember.

"I am certainly aware of quite a number of tractors, as well as baling and slurry equipment, sold from scratch at the event.

"The mood, both among exhibitors and visitors, was upbeat - perhaps surprisingly so."

He went on to say, "The changed layout of the event, along with the increased size and standard of presentation of many stands, got a very positive response.”

The FTMTA Farm Machinery Show, an exhibition that it describes as the “flagship event for the Irish agricultural machinery sector", had over 160 trade exhibitors, the largest such event ever held.

The show was fully sold out by the end of October.

However, additional space was subsequently made available most of which was booked.

The winner of the six short-listed ‘Working Wonders’ that featured at the FTMTA Farm Machinery Show - as part of a country-wide competition - was a tractor belonging to the Bailey family from Gorey, Co. Wexford, which received the most votes at the event in Punchestown.

Bob Bailey’s son Ben said that their Fiatagri 160-90 DT was purchased from Kelly’s of Borris, Co. Carlow, in 1994.

The tractor is now spends its evenings distributing feed rations to cattle (with a diet feeder in tow).

During past harvest seasons it was driving a beefy Hesston 8X4X4 big square baler.

It also pulled a 4m-wide Cousins press/roller during the sowing season.

Ben explained, "There are about 28,000 hours on it.”

The Baileys have now won €3,000 worth of tyres – kindly sponsored by FTMTA member firm AgriGear who are based in Bailieborough, Co. Cavan.

|  |

NEW MASSEY FERGUSON DEALER FOR CO. LIMERICK

Whelan's Garage appointed

Whelan’s Garage is already an established dealership in counties Clare and Galway, with depots in Kilrush, Ennis and Loughrea.

Whelan’s Garage is already an established dealership in counties Clare and Galway, with depots in Kilrush, Ennis and Loughrea.

They employ over 40 staff & have six service vans on the road.

The business also has franchises for Fendt, Kverneland, Lely, Kubota Groundcare, Husqvarna and Honda.

Until recently Nunan Farm Machinery (Broadford) was the Massey Ferguson dealer for Co. Limerick.

The company was established in 1966 by Joe Whelan Senior, who grew up on the family farm and agricultural contracting business.

He trained as a mechanic with the Air Corps in Baldonnell, Co Dublin.

Joe then acquired the Zetor agency and established his farm machinery business at the old railway station in Kilrush.

In 1982 he acquired the Ford tractor agency.

They sold Ford alongside Zetor up until 1995, when a new dealership was appointed to cover Clare and Limerick which was now the New Holland agency.

In 1996 Joe acquired a Renault tractor agency which they continued to sell until the Claas and Renault merger in 2004.

Joe Junior joined the business in 1996 as a sales executive and is the current Sales Manager.

In 2005 Whelan’s took on the Massey Ferguson franchise.

Joe’s other son Kevin joined the business that year as a parts and store manager, which is a major responsibility as they carry over €1.5m worth of spare parts in stock.

25 years ago new sales accounted for 30% of their business, with second-hand machinery making up the other 70%. Today it is 60% new and 40% second-hand.

Kevin and Joe Whelan run a professional business which provides a quality service to their customers and the family business has prospered because of this policy.

|  |

STRONG TRACTOR SALES

In Ireland for Jan 2019

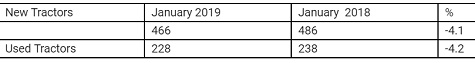

Sales for new and used tractors were buoyant for January but down around 4% on January 2018.

As can be seen from this data in the table below from the Revenue Commissioners tractor sales for new and used tractors were buoyant for January - but down around 4% on January 2018.

However allowance as to be made for the increasing HP of the tractors sold.

AGRIFAC TO TAKE OVER HARDI'S BUSINESS

From March 1st

Both brands will continue to work as separate entities under the EXEL Industries Group of whom they are owned by, to 'develop plans for future demands in plant protection'.

It has been announced that from March 1st 2019, Agrifac UK will take over the business of HARDI UK.

An official statement said, "With both brands being committed to the long term development of crop protection, as well as being subsidiaries of the EXEL Industries Group, the merge between the two companies is seen as an appropriate and positive step forward for the future production of crop spraying equipment."

Both brands will continue to work as separate entities under the EXEL Industries Group of whom they are owned by, with Agrifac providing local support for HARDI UK from their UK base. Support will consist of sales, marketing, service, parts, finance and administration activities, and will mean that the two companies will work in synergy with one another.

Spare part support and handling for HARDI UK customers will be taken care of by HARDI North until June 2019 to secure optimal deliveries and service to dealers and end-users. Parallel with this, spare part facilities will be available from the UK, and training of back-office will be carried out.

HARDI representatives from across the UK will remain the face of the brand to the market, with the takeover bounding no change on existing relationships with current and prospective customers of each of the separate brands. Improvements will be made to support HARDI UK to allow and prepare for future growth, as well as enable the brand to meet the demands and pressures of the market.

In addition, support will be provided across the HARDI UK dealer network by way of importing of machines. Agrifac UK will now import HARDI products, which will continue to be distributed through the HARDI UK dealer network.

After the success of Agrifac UK partnering with HOLMER Maschinenbau back in 2013, another subsidiary of the EXEL Industries Group, Agrifac UK and HARDI UK say they are keen at the prospect of mirroring this partnership and developing the brands similarly. It is hoped that the takeover will play a huge part in the longevity of crop protection within the industry, and over time, will enable new innovations to be produced along with a more forward thinking way of protecting and nourishing the land.

Andy Carse, managing director at Agrifac UK said, “We really believe that joining together with HARDI UK will help develop and support customer relations; something that is imperative for such a huge name within the industry. The in-house operations we can lend to HARDI UK will prove a tremendous help. With current support to the UK dealer network only available from overseas teams, consolidating this within the UK means we can help HARDI streamline their efforts, and target the UK market more efficiently and effectively.”

Peter Dahl, sales and marketing director for HARDI North added: “The demands for high service capability and parts supply will be much higher in the future. With joint forces between the two specialists, HARDI and Agrifac, we will continue the development solutions for end-users to offer the best plant protection within the marketplace.”

|  |

JOHN DEERE DEVELOP ELECTRIC CABLE POWERED TRACTOR

Part of company's ongoing R&D work

The GridCON research project and tractor are part of the company’s continued efforts in the electrification of agricultural machinery.

John Deere has developed an electric cable powered tractor developing up to 400hp.

The GridCON research project and tractor are part of the company’s continued efforts in the electrification of agricultural machinery, offering new opportunities for farms to supply and use their own energy.

John Deere GridCON tractor

John Deere presented the first fully electric tractor, known as the SESAM (Sustainable Energy Supply for Agricultural Machinery), in 2016. The GridCON tractor looks very different to its predecessor, as it features no cab and no rows of batteries underneath the bonnet. The manufacturer says it is the first vehicle to be fully electric, permanently cable powered and capable of fully autonomous operation in the field.

Based on a John Deere 6210R tractor, GridCON utilises a cable connection from the field border to the machine, which transfers power continuously at over 300kW. A 100kW electric motor powers the IVT transmission, and there is an additional outlet for implements powered by a 200kW electric motor.

A drum fixed to the tractor carries up to 1000m of cable, although the length can be extended if required. In the field, the cable is fed out and reeled in while guided by a robot arm to keep the operation friction free and at low load. An intelligent guidance system is also used to prevent the tractor running into or over the cable.

At work, the tractor follows preset rows fully autonomously at operating speeds of up to just over 12mph (20kph). The vehicle can also be guided manually using a remote control, which is particularly useful when manoeuvring the tractor to start work on field borders for example.

A power supply of 2.5kV AC is required, and the GridCON tractor uses a 700V DC bus for electric power distribution both onboard and for implements. The machine employs a cooling infrastructure for off-board electrical use, while total efficiency of the drivetrain is in the region of 85 per cent.

Total empty weight of the working prototype GridCON tractor including cable drum and robot arm is about 8.5 tonnes, so it is about the same weight as a conventional John Deere 6195R tractor but with twice as much power. Research engineers are aiming to reduce the weight further by at least one tonne.

Besides this favourable power to weight ratio, the concept offers the twin benefits of noiseless and emission-free operation. Compared to battery-powered tractors, the GridCON tractor also delivers around 50 per cent lower machine and operating costs.

|

|

|  |

ADVERTISE YOUR JOBS HERE

Amazing success rates!

Advertise your recruitment needs on Serivce Dealer Weekly Update Ireland and reach our targeted audience of recipients every week.

Contact Nikki Harrison for details - 44 01491 837117

|

SHOWCASE YOUR NEW PRODUCTS HERE

Have your new equipment seen first!

Use this Ireland Weekly Update to showcase your new products to our ever-growing community of specialist dealers.

Contact Nikki Harrison - 44 01491 837117

|

|

|