HIRING PROBLEMS?

Ireland is enjoying almost full employment

by Service Dealer Ireland Editor, Alan Mahon

If you are struggling to fill roles there is an option of going down the apprenticeship route.

Last month I brought my car to the nearest NCT centre for its annual check-up. It should have been seen weeks earlier but, because of a shortage of mechanics in the NCT centres all over the country, there was a long waiting list of cars that needed to be tested. When I did eventually bring my car for testing it, not surprisingly, failed the test. Some parts needed replacing so I phoned my local mechanic, John, to see if he could book me in for a repair slot.

John has been my mechanic for many years. He lives locally and is self employed. John has gained the respect within the parish as a talented mechanic. He recently moved location to a bigger premises as his original garage was getting too small. It was always full of cars waiting to be repaired - a sign of a good mechanic. His new set up is much bigger and better, which should help him a lot.

In a strange way the problem about being good at your job is that you get a lot of business so, in order to keep up with the demand, you need to take on extra staff. It all sounds simple but finding the right people is not always easy, especially if you are looking for someone with qualifications and experience, such as a motor mechanic.

Because John had expanded his business he needed more mechanics to cater for the extra demand. This was a real challenge for him. John is not alone in this regard. Many of us have been in this situation before and some are still finding recruiting good staff extremely difficult. Hanging on to them is just as difficult.

Ireland is enjoying almost full employment at the moment and long may it continue. The downside of this, for employers, is that there are less fish in the pond to choose from.

But all is not doom and gloom. There is an option of going down the apprenticeship route. Generation Apprenticeship has a scheme where employers can register to take on apprentices during their training. Apprenticeship employers are formally approved by SOLAS in advance of employing apprentices. Generation Apprenticeship has an Agricultural Mechanics Level 6 course which takes 4 years to complete. There are 7 phases within the course. Phases 1, 3, 5 and 7 are with the employer while Phases 2, 4, and 6 are spread between training centres and educational colleges.

If you are interested in hiring an Agricultural Mechanic Apprentice you must register with Generation Apprenticeship. The Education & Training Board (ETB) facilitate these courses so there may be a centre near your area. You will need to complete an expression of interest on Apprenticeship Online. Once they have received your application and you are approved, you can advertise your apprenticeship vacancies on apprenticeship.ie

When I last checked their website there were 13 motor mechanic apprenticeship jobs available. Visit www.apprenticeshiponline.ie to find out more about taking on apprentices.

Today is the day that I am scheduled for my NCT re-test. I’m hoping that John will have the parts properly fitted and that my car will pass the test. Fingers crossed!!

|

|

|  |

BUSINESS CLIMATE CONTINUES UPWARD TREND

According to CEMA report

Association says a slowdown in demand is not in sight in the short term.

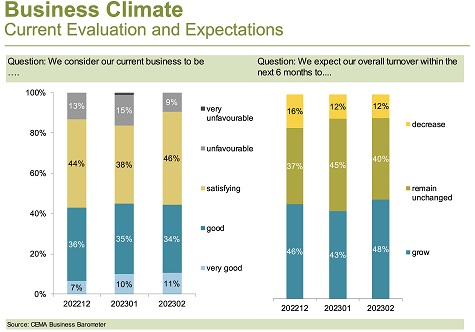

According to the latest monthly CEMA report for February, the general business climate index for the agricultural machinery industry in Europe has continued its first significant upward trend since the sharp declines in the course of the Russian war against Ukraine.

In February, the index increased from 30 to 36 points (on a scale of -100 to +100).

A slowdown in demand is not in sight in the short term and in addition to a strong demand side, now, finally, considerable easing is arriving on the supplier side.

Bottlenecks continue to challenge the industry and the volume of orders corresponds currently to a production period of 6.9 months, which is another all-time high ever recorded within this survey. However, order backlogs may now finally have reached their maximum. Manufacturers are increasingly able to realize their orders, which increases the current turnover and turnover expectations accordingly.

LOW EMISSION FUEL USE APPROVED

For diesel engines

HVO (Hydrotreated Vegetable Oil) and GTL (Gas To Liquid) fuel approved by manufacturer for use in all its diesel engines.

Kubota (UK) Ltd has approved use of the paraffinic fuels HVO (Hydrotreated Vegetable Oil) and GTL (Gas To Liquid) in all its diesel engines, which they say will contribute to a lower carbon footprint for Kubota internal combustion engines.

Approval follows the company's internal evaluation of these alternative fuels. It has confirmed that any paraffinic fuel that complies with the European standard EN15940, is suitable for use in all its diesel engines.

“This is a tremendous benefit for operators who are required to meet environmental conditions where CO2 emissions are monitored and measured,” explained Tim Yates, Kubota (UK)’s agricultural and ground care sales manager. “For those working in urban locations for example, or with county councils and environmental projects, achieving a lower carbon footprint is now possible with Kubota powered equipment.”

The manufacturer says they recognise that HVO, which is synthesised from vegetable oil and fat, and GTL which is synthesised from natural gas, are becoming increasingly popular as alternative fuels due to their environmental benefits that offer reduced emissions.

Tim continued, “This is another example of Kubota’s engineering excellence, to enable a change in approved fuel without any modification. It provides owners and operators with yet another fuel choice, to suit their operating environment.”

When using these fuels, operators should comply with any appropriate local regulations in the areas being used say Kubota. There is no requirement to flush fuel tanks or change filters, as HVO and GTL are safe to mix with diesel. Nor are there changes to existing maintenance intervals or warranty conditions when using these fuels. Operators may notice a slight degradation in engine performance from using the lower density paraffinic fuels, compared to diesel.

|  |

FUTURE TECH PARTNERSHIP ESTABLISHED

By major manufacturer

Machinery maker says new collaboration with software company will create new ways to enhance their equipment.

Bobcat Company has announced they have partnered with Agtonomy, to collaborate in the areas of electrification, autonomous operation and digital technology.

Through this partnership Bobcat say that they and Agtonomy, a Silicon Valley agtech software company, will collaborate to create new ways of enhancing Bobcat equipment for increased productivity and performance.

Together, the companies say they will focus on addressing pressing issues in agriculture by developing electric-powered and autonomously operated solutions.

“The agriculture industry offers many opportunities for innovation advancements, and we are focusing on developing solutions for real-world application,” said Joel Honeyman, Bobcat Company vice president of global innovation. “Through this partnership with Agtonomy, we are identifying ways to make our customers more productive and efficient in their ag operations.”

Agtonomy say their focus is on developing solutions for farmers that allow them to remotely complete day-to-day tasks, more efficiently and with more precision.

“We are ecstatic to be joining forces with Bobcat in utilising technology to make farming operations more productive, profitable, and sustainable” said Tim Bucher, CEO and co-founder of Agtonomy “With our shared commitment to innovation, we are confident that we can develop solutions to overcome some of the biggest challenges facing agriculture today.”

|  |

MASS PRODUCTION OF HYDROGEN ENGINES

Set for 2025 by major manufacturer

Prototype to be rolled out in 2023, validation on vehicle in 2024, and full-scale mass production in 2025 announced.

Hyundai Doosan Infracore (HDI), producers of the Bobcat range of equipment, have announced an acceleration in their engine development after finishing the design of its hydrogen internal combustion engines (hydrogen engines) and rolling out the prototype.

The hydrogen engine under development by HDI is an 11-litre class engine that they say produces a power output of 300 kW (402 HP) and a torque of 1700 Nm at 2000 RPM. It satisfies Tier 5 / Stage 5 / Euro 7 regulations which require the emission to be 90% reduced to the current level to meet Zero CO2 (below 1g/kwh) and Zero Impact Emission (Zero Emission in EU).

Hydrogen engines are powered by low-purity hydrogen, making them durable, economical and energy-dense, which HDI believes makes them the most suitable engine system for mid-to-large-sized vehicles and vehicles for long distances. A single charge of 10 minutes enables a distance of up to 500 km, and HDI claim they are 25-30% more economical than fuel cells or battery packs when vehicle price and maintenance costs are considered.

HDI say they plan plan to leverage its existing engine technology and facilities to reduce costs and accelerate commercialisation. The new hydrogen engines will be installed on commercial vehicles such as trucks and large buses, and construction equipment for validation by 2024, and full-scale mass production is planned for 2025.

HDI will showcase various products including H2ICE, EV battery packs and plug-in full hybrid powertrains at the upcoming CONEXPO 2023 to be held in the U.S. in March.

HDI’s head of the engine department, Kim Joong-soo, said, “Hydrogen internal combustion engines will be used in mid-to-large-sized commercial vehicles such as trucks, buses and construction equipment and mid-to-large-sized power generators. We will put in the utmost effort to realize carbon neutrality in response to the eco-friendly market by developing green hydrogen-related technologies in line with increasingly strict carbon emission regulations."

|  |

OVERTAKEN BY A MAN WITH A FRIDGE ON HIS BACK!

But Duncan & Emma complete Brighton Half Marathon

Service Dealer Ireland owners Duncan Murray-Clarke and Emma Craigie completed the event recently, raising cash for The Addington Fund.

Service Dealer Ireland owners Duncan Murray-Clarke and Emma Craigie completed the Brighton Half Marathon recently, raising cash for The Addington Fund.

Describing the race Duncan said, "Just when I thought I was doing well, I was passed by a man with a fridge on his back!

"Seriously though, thanks to all our sponsors for helping us pass our £1,000 target and especially Kubota UK for sponsoring my head!. Congratulations also to Sam Hammond for his great work for SSAFA, the Armed Forces charity."

You can still back Duncan and Emma in their quest to raise cash for The Addington Fund, the charity supporting farming and rural communities, by visiting their Gofundme page.

AMAZONE ANNOUNCE DEATH OF LONGSTANDING CEO

Dr. Heinz Dreyer

Company describe Dr Dreyer as an unparalleled inventor from the agricultural machinery sector and a passionate family business owner.

Shareholder and longstanding CEO of the Amazone Group, Prof. h.c. Dr. Dr. h.c. Heinz Dreyer, passed away on 17 February 2023 at the age of 90.

Dr. Heinz Dreyer

In a statement Amazone said they had lost "an unparalleled inventor from the agricultural machinery sector and a passionate family business owner".

Dr. Heinz Dreyer decisively shaped sustainable development in the Amazone Group for many decades. As soon as he joined the company management in 1958, he demonstrated a strong commitment to research and product development. The development of agricultural machinery was always for him a matter very close to his heart.

Numerous pioneering inventions and patents can be related back him. For example, he invented the first ZA three-point linkage mounted, twin disc fertiliser spreader, which later became the forerunner to almost every other fertiliser spreader used around the world. He set further milestones with the design of seed drills for larger working widths and invented the Amazone D4 tractor-mounted seed drill, which soon enabled the company to become market leader in this field as well.

Ahead of his time, he turned his attention to the progressive method of direct seeding as early as 1975 and invented a ground-breaking chisel opener for this purpose. His achievements were recognised in many ways. Over the years, he came up with a large number of inventions which received many awards and medals for these many advancements in agricultural machinery. Dr Heinz Dreyer himself received top-level scientific awards and important honorary degrees for his work.

As the third generation of the Dreyer family, Dr Heinz Dreyer played a major role in building up the company and developed it into a global agricultural machinery manufacturer with his business acumen. The continued independence of the owner-managed family business was always at the centre of his considerations. He transferred his management responsibilities to his son, Dr. Justus Dreyer, in 2005. Nevertheless, he continued to be still responsible for Amazone seeding systems and their optimum fertilisation and maintained strong links with universities.

Amazone concluded, "The death of Dr. Heinz Dreyer has left a huge hole in our company. The family, the entire management team and all employees will respectfully continue his life's work."

|

|

|  |

Sponsored Product Announcements

|

MEET YOUR NEW FUEL TANK

Professional performance from the Kress 60V Commercial range

Now commercial landscapers can save money by switching from petrol to Kress battery powered outdoor equipment.

Until recently, despite a growing environmental awareness, commercial landscape professionals have been forced to accept high-emission, petrol-powered outdoor equipment as the only economical option that provides them with the performance and runtime required to complete a full day’s work. Battery-powered equipment simply has not been a viable alternative due to the expense of multiple battery packs, the hassle of overnight charging and the high cost to replace dead battery packs after only a few months of daily re-charging.

Recent innovations from Kress have changed all of that: now commercial landscapers can even save money by switching from petrol to Kress battery powered outdoor equipment, making the change not only the right thing to do for the environment but a viable business model. Based on the current high prices of fuel, a typical landscaping business can recoup their investment in the Kress battery-powered equipment in a short space of less than three years. Kress is leading the transition from petrol-powered lawn and garden equipment with the introduction of the industry’s first true game-changing innovation in battery-powered equipment, the Cybersystem revolutionary ultra-fast charger which allows 8 minute charge times and batteries which last 10 times longer than the average lithium battery. Combined with an unprecedented 8-year commercial warranty which removes the risk, the business case really does stack up.

Fast-charging and long-lasting, the Kress 60V Commercial Pack unlocks new levels of productivity for all types of landscaping professionals. Powering an impressive line of commercial equipment, this battery platform stands strong in harsh conditions and delivers unparalleled reliability—all without the high costs and hassles of petrol power. Kress are offers lawncare professionals the opportunity not only to save the planet, but to save money as well.

Learn more about the Cybersystem technology and browse the Kress 60V Commercial range here: https://www.kress.com/en-gb/8-minute-fastest-battery-charge/

|  |

SHOWCASE YOUR NEW PRODUCTS HERE

Have your new equipment seen first!

Use this Ireland Weekly Update to showcase your new products to our ever-growing community of specialist dealers.

Contact Nikki Harrison - 44 01491 837117

|

|  |

ADVERTISE YOUR JOBS HERE

Amazing success rates!

Advertise your recruitment needs on Serivce Dealer Weekly Update Ireland and reach our targeted audience of recipients every week.

Contact Nikki Harrison for details - 44 01491 837117

|

|

|